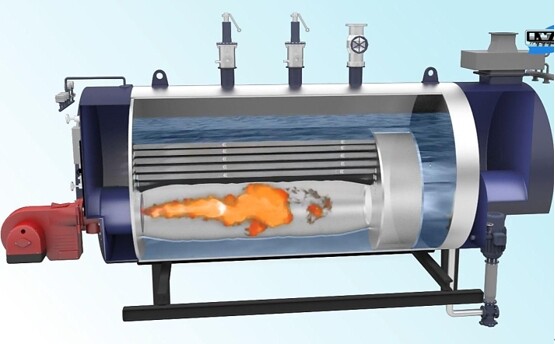

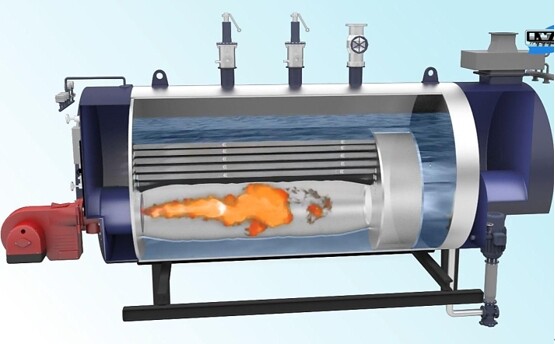

The fire tube boiler is a simple and

economical boiler that has been used since the 18th century. It relies on

burning fuel in the furnace to heat water in the fire tube to generate steam.

The fire tube boiler consists of a furnace body, tubes, flue and control

system, among which the boiler

tube is an important part of the fire tube boiler.

Fire tube boiler tube structure

The fire tube boiler tube structure is

relatively simple, usually composed of straight tubes, elbows and expansion

joints.

1. Straight tube

The straight tube is the most basic tube

form in the fire tube boiler. The straight tube is usually made of medium-thick

or thin-walled seamless

steel pipe or mild

steel tubes. The outer layer of the straight tube is usually covered with

an insulation layer to reduce heat loss and reduce the surface temperature of

the boiler and improve safety.

Material selection: 20# carbon steel/304

stainless steel

Wall thickness standard: 3mm/5mm/8mm

Insulation layer: aluminum silicate fiber +

galvanized iron sheet (anti-scalding design)

2. Bend tube

Bend tubes are mainly used to form a water

tube membrane shell structure. An important function of pipe bending is to make

water flow smoother instead of being hindered by the inside of the pipe. Pipe

bending usually adopts cold drawing manufacturing process to ensure the finish

and dimensional accuracy of the inner wall of the pipe.

Bending radius specification: ≥3 times the pipe diameter (ASME standard)

Welding requirements: Argon arc welding

full welding process (key points for leak prevention)

3. Expansion joint

The expansion joint is composed of two pipe flanges and

a hose in the middle, which is mainly used to compensate for the linear

expansion of the pipeline during temperature changes. Expansion joints are

usually made of metal materials and can withstand high temperatures and high

pressures.

Compensation calculation: 5mm expansion

space needs to be reserved for every 100℃ increase in

temperature

Replacement cycle: 3 years/5000 working

hours

Fire tube boiler tube features

1. Small size and light weight

The pipe structure of the fire tube boiler

is simple and relatively small. The density is relatively small under the same

working pressure, so it is light in weight, which has the same advantages as

the lightweight design of some hydraulic

tubes.

2. Fast heat transfer speed

By injecting high-temperature gas directly

into the water tube, the fire tube boiler tube can quickly heat the water to

the evaporation temperature, thereby increasing the heat transfer speed.

3. Compact structure

The tube layout in the fire tube boiler is

very compact, with almost no spare space, so it can efficiently complete heat

exchange in a small space.

4. High fire risk

Since the tubes in the fire tube boiler are

in direct contact with the fuel, the fire risk is relatively high. In addition,

due to the complex internal structure of the tube, if it is not regularly

inspected and maintained, the risk of tube bursting will increase.

Common failures of fire tube boiler

tubes

1. How to deal with the problem of water

leakage in fire tube boiler tubes in an emergency?

Emergency symptoms: water seepage in the

tube wall > 200ml/min, steam pressure drops by 15%

Emergency plan:

Turn off the combustion system and reduce

the pressure to 0.2MPa.

Wrap 3 layers of high-temperature resistant

epoxy tape (3M 2216 recommended).

External reinforcement stainless steel

clamp (spacing ≤150mm).

2. How to check the decrease in heat

transfer efficiency of fire tube boilers?

Warning indicators: Fuel consumption

increased by 20% | Steam production decreased by 30%

Emergency plan:

Internal scale: Use endoscope measurement

method to detect, thickness ≥ 2mm needs pickling

(hydrochloric acid concentration 10%).

External ash accumulation: Use U-type

differential pressure gauge to detect, and blow when the flue gas pressure

difference is > 150Pa.

Insulation failure: Scan with infrared

thermal imager, surface temperature rise > 40℃ needs

to be replaced.

3. What are the signs before the boiler

tube bursts?

Abnormal sound characteristics:

Intermittent metal knocking sound (> 85

decibels)

Accompanied by 2-5Hz low-frequency

vibration (detectable by mobile phone APP)

Abnormal temperature:

Sudden increase in temperature difference

between adjacent pipe sections > 30℃

Local overheating and reddening (> 450℃)

Summary

The fire tube boiler tube is one of the

most important components of the fire tube boiler, which directly affects the

performance and service life of the boiler. Through a deep understanding of the

structure, material and characteristics of fire tube boiler tubes, we can

better understand the operating principle of this traditional boiler, and can

also maintain and service it more accurately to extend its service life.

Read more: How To Weld Boiler Tubes? or Material of Boiler tube

Eastern Steel Manufacturing Co.,Ltd not only improve product production and sales services, but also provide additional value-added services. As long as you need, we can complete your specific needs together.

Eastern Steel Manufacturing Co.,Ltd not only improve product production and sales services, but also provide additional value-added services. As long as you need, we can complete your specific needs together.