Pickling is mainly suitable for metal pipes

such as steel pipes and cast iron pipes. It can effectively remove impurities

and rust on the inner wall of the pipe, making its surface smoother and more

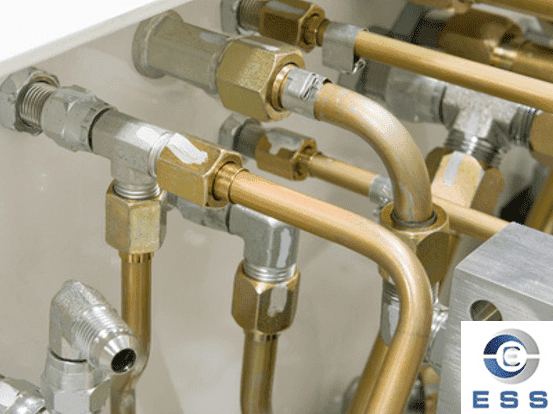

delicate, and improving the efficiency of the pipeline to transmit liquid. The hydraulic

tubes are pipes used to transport liquid or convert liquid into mechanical

energy. Hydraulic tube is one of the seamless

steel pipe. Hydraulic tubes must be pickled before use, because pickling

can effectively remove impurities and rust on the inner wall of the pipe,

ensuring the cleanliness and service life of the pipe.

The process of pickling hydraulic tubes

During the production process of hydraulic tubes, due to material reasons or friction during processing, there will be

some impurities such as rust, steel slag, and scrap iron on the surface of the

pipe. These impurities will have a certain impact on the service life and use

effect of the pipe, so the pipe needs to be pickled.

The process of pickling hydraulic tubes

includes the following steps:

1. Cleaning: First clean the surface of the

hydraulic tube with clean water or cleaning agent to remove most of the dust

and impurities.

2. Pickling: In a specific acidic

environment, soak the hydraulic tube for a period of time so that the rust,

steel slag, scrap iron and other impurities on the surface of the pipe are

dissolved and removed by acid.

3. Cleaning: After pickling, the hydraulic tube needs to be thoroughly cleaned with clean water, and alkali solution is

used to neutralize the residual acidity to avoid affecting the service life of

the pipe.

The role of hydraulic tube pickling

The main role of hydraulic tube pickling is

to remove impurities on the surface of the pipe, improve the smoothness and

roughness of the pipe surface, reduce the resistance inside the pipe, and thus

improve the use effect and service life of the hydraulic tube.

In addition, the hydraulic tube treated

with pickling also has the following characteristics in the later use process:

1. The surface of the pipe is smooth, and

it is not easy to adhere to dirt and impurities, which is convenient for

cleaning and maintenance.

2. The inner wall of the pipe is smooth and

the friction coefficient is small, which can effectively reduce the pressure

loss and energy consumption of the pipe.

3. The flatness and straightness of the

pipe surface are increased, which can ensure the smooth and stable flow of

liquid or gas, and is conducive to industrial automation control.

The necessity of pickling hydraulic tubes

1. Ensure the normal operation of the

hydraulic system: The low finish of the inner wall of the pipe will have a

great impact on the operation of the hydraulic system. For example, sediments

will increase the friction resistance of the pipe, reduce the transmission

flow, and even cause the pipe to be blocked; while oxides will damage the

structure of the pipe and cause leakage.

2. Extend the service life of the hydraulic

system: The inner wall of the pipe treated with pickling is smoother, which can

prevent scale, corrosion and rust, thereby extending the service life of the

pipe.

The impact of not pickling the pipe

1. Increased resistance: Impurities and

rust on the inner wall of the pipe without pickling are difficult to remove,

which will increase the resistance of the pipe and reduce the efficiency of

transmitting fluid.

2. Leakage: The unpickled part of the inner

wall of the pipe is prone to oxides and rust, which may cause the pipe to age

and crack, thus causing leakage.

Conclusion

Hydraulic tubes must be pickled before use.

Only by thoroughly cleaning the impurities and rust on the inner wall of the

pipe can the finish and smoothness of the pipe be guaranteed, and the

efficiency of transmission flow and fluid can be improved, thereby ensuring the

normal operation of the hydraulic system and extending its service life.

Eastern Steel Manufacturing Co.,Ltd not only improve product production and sales services, but also provide additional value-added services. As long as you need, we can complete your specific needs together.

Eastern Steel Manufacturing Co.,Ltd not only improve product production and sales services, but also provide additional value-added services. As long as you need, we can complete your specific needs together.