Steel casing pipe is a vital tool used in

drilling and oil and gas development. It consists of a steel pipe on the

outside and a casing

pipe on the inside. It primarily supports the wellbore, maintains the

wellbore, and limits the leakage of oil, gas, and groundwater.

Steel casing pipe is typically made of

high-strength steel, with common materials including carbon steel, alloy steel,

and stainless steel. These materials offer advantages such as high strength and

corrosion resistance, making them suitable for use in harsh environments.

Due to its unique structure and

performance, steel casing pipe has a wide range of applications in various

fields and situations. The following is a detailed summary of the uses of steel

casing pipe:

Construction

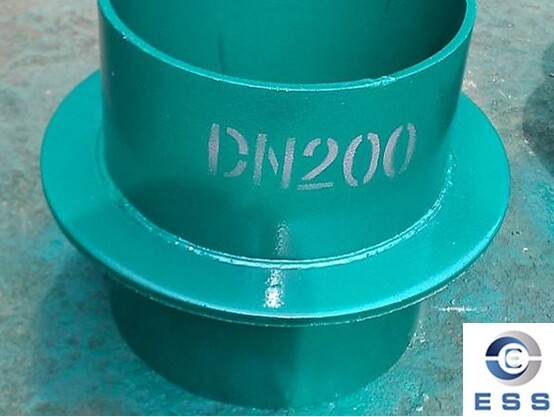

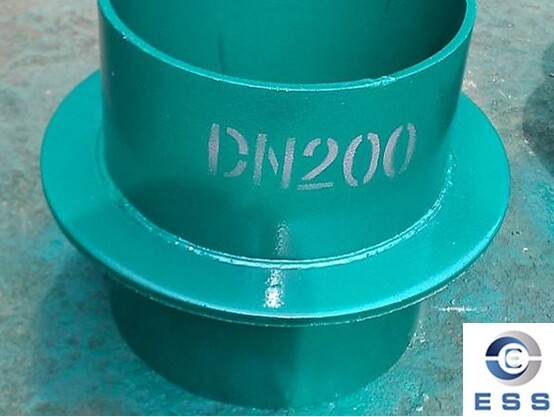

1. Water Supply and Drainage Systems

In water supply and drainage systems, steel

casing pipe is widely used for pipes passing through walls, floors, and other

structural elements. It not only provides the necessary channel for pipe

installation but also effectively prevents water waste and leakage through its

excellent sealing properties.

2. Electrical Systems

Steel casing pipe also plays an important

role in electrical systems. They are used for routing electrical wires, cables,

and other electrical equipment through conduits, protecting them from

environmental damage and ensuring the safe and stable operation of the

electrical system.

3. HVAC Systems

The piping systems in HVAC systems need to

pass through walls, floors, and other structural components. Steel casing pipe

provides convenient passage for these pipes and ensures the sealing and

stability of the piping system.

4. Firefighting Systems

In firefighting systems, steel casing pipe

is used for routing fire hoses, providing essential protection and ensuring

rapid response and effective firefighting in emergencies.

Drilling and Oil and Gas Development

1. Well Support

Steel casing pipe effectively supports the

wellbore, preventing it from collapsing and deforming during drilling, thereby

ensuring drilling quality.

2. Wellbore Maintenance

Steel casing pipe prevents wellbore

collapse and landslides, ensuring wellbore stability and safety.

3. Oil and Gas Leakage Control

Steel casing pipe prevents oil and gas

leakage and groundwater contamination in oil and gas wells.

4. Facilitating Production Operations

Production casing pipe can make production

operations smoother and more efficient, and has a wide range of applications in

oil and gas wells, water wells, and other fields.

Transportation

1. Subway Engineering

In subway construction, steel casing pipe

is used as a protective measure for tunnel walls. It enhances tunnel stability

and reduces the risk of tunnel collapse.

2. Highway Construction

In highway construction, steel casing pipe

is used for bridge abutments, guardrails, and road drainage systems. Its

advantages lie in its excellent compressive strength and long service life.

Hydraulic Engineering

1. Sluice Construction

Steel casing pipe is widely used in

hydraulic engineering projects, such as supporting bridges and pipelines in

sluice construction. Its corrosion resistance and strength ensure the stability

and safety of sluices.

2. Hydraulic Equipment

In hydraulic equipment, steel casing pipe

is used in pump wells and well equipment, performing functions such as

diversion, securing, and isolation.

Other Applications

1. Geothermal Wells, Coalbed Methane, and

Coalfield Mining

Steel casing pipe also has a wide range of

applications in these areas, primarily for supporting and protecting well walls

and preventing groundwater and gas leakage.

2. Enclosure and Insulation Materials for

Plastic Windows and Doors

Steel casing pipe can serve as enclosure

and insulation materials for these products, providing excellent sealing and

thermal insulation.

Summary

In summary, steel casing pipe, due to its

unique structure and properties, has a wide range of applications in

construction, drilling, oil and gas development, and many other fields. These

applications not only demonstrate the versatility and practicality of steel

casing pipe but also strongly support its widespread application across various

industries.

Read more: A Comprehensive Guide To Steel Casing Pipe or One-Piece vs. Split Steel Casing Pipe

Eastern Steel Manufacturing Co.,Ltd not only improve product production and sales services, but also provide additional value-added services. As long as you need, we can complete your specific needs together.

Eastern Steel Manufacturing Co.,Ltd not only improve product production and sales services, but also provide additional value-added services. As long as you need, we can complete your specific needs together.