Application of seamless pipes in fire water supply systems

Fire protection is a critical aspect of ensuring the safety of lives and property in various industrial, commercial, and residential settings. One of the key components of an effective fire protection system is a reliable fire water supply system. In this comprehensive article, we delve into the application of seamless pipes in fire water supply systems. Seamless pipes play a pivotal role in ensuring the efficiency, durability, and safety of these systems. We explore the characteristics of seamless pipes, their advantages over other pipe types, and their specific applications in fire water supply systems. Additionally, we discuss the importance of proper material selection, installation techniques, and maintenance practices to enhance the overall performance of seamless pipes in fire protection scenarios.

1. Introduction

1.1 Importance of Fire Water Supply Systems

Fire incidents pose a significant threat to life, property, and the environment. Timely and efficient response to a fire emergency requires a well-designed and properly functioning fire water supply system. These systems are integral components of fire protection infrastructure in industries, commercial buildings, residential areas, and public spaces. A reliable fire water supply system ensures the availability of water in adequate quantities and at the right pressure for firefighting activities.

1.2 Role of Pipes in Fire Water Supply Systems

Pipes are the arteries of fire water supply systems, responsible for transporting water from its source to the point of use. The selection of the right type of pipes is crucial to the effectiveness and reliability of the entire system. Seamless pipes, in particular, have gained prominence due to their unique characteristics that make them well-suited for demanding applications like fire protection.

2. Seamless Pipes: Characteristics and Advantages

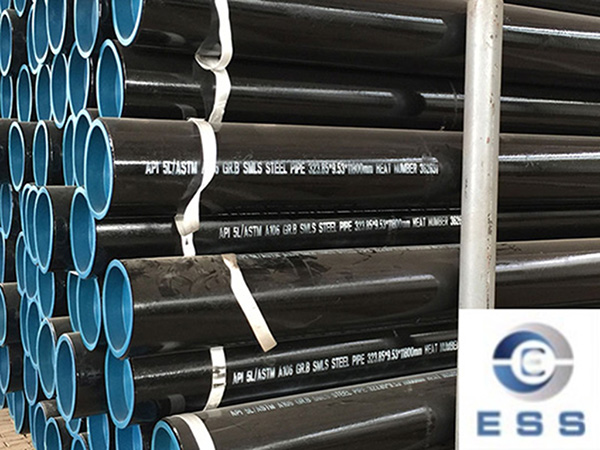

2.1 What are Seamless Pipes?

Seamless pipes are tubular products without any welded seam. They are manufactured by extruding a solid billet through a piercing rod to create a hollow tube. This seamless construction imparts several key characteristics that set seamless pipes apart from other types of pipes.

2.2 Key Characteristics of Seamless Pipes

Strength and Durability: Seamless pipes exhibit superior strength and durability, making them suitable for high-pressure applications. The absence of weld seams eliminates potential weak points, reducing the risk of pipe failure.

Corrosion Resistance: Seamless pipes are often made from corrosion-resistant materials such as stainless steel or alloy steel. This corrosion resistance ensures a longer service life, even in harsh environments.

Smooth Interior Surface: The seamless manufacturing process results in a smooth interior surface, minimizing friction and pressure loss in the flow of water. This characteristic is particularly beneficial in fire water supply systems where rapid water delivery is critical.

Uniformity: Seamless pipes offer uniform dimensions and properties, contributing to consistent performance in various conditions.

2.3 Advantages of Seamless Pipes in Fire Water Supply Systems

Reliability in High-Pressure Environments: Fire water supply systems often require pipes to withstand high pressures to deliver water effectively during firefighting. Seamless pipes excel in such conditions, providing a reliable conduit for water flow.

Reduced Risk of Leaks: The absence of weld seams in seamless pipes minimizes the risk of leaks, ensuring that water reaches its destination without losses or disruptions.

Low Maintenance Requirements: Seamless pipes require less maintenance compared to pipes with weld seams. The reduced need for repairs and replacements contributes to cost savings over the life of the fire water supply system.

Compatibility with Corrosive Environments: In industrial settings, where corrosive agents may be present, seamless pipes made from corrosion-resistant materials prove to be highly effective, maintaining their integrity over time.

3. Material Selection for Seamless Pipes in Fire Water Supply Systems

3.1 Stainless Steel Seamless Pipes

Stainless steel seamless pipes are widely used in fire water supply systems due to their excellent corrosion resistance, strength, and versatility. The alloying elements in stainless steel, such as chromium and nickel, contribute to its resistance against rust and corrosion, making it an ideal choice for long-term durability.

3.2 Alloy Steel Seamless Pipes

Alloy steel seamless pipes are another common choice for fire water supply systems, especially in applications where high strength and resistance to elevated temperatures are essential. The addition of alloying elements like chromium, molybdenum, and nickel enhances the mechanical properties of the pipes, making them suitable for demanding conditions.

3.3 Other Materials

While stainless steel and alloy steel are predominant choices, seamless pipes can also be manufactured from other materials based on specific project requirements. These may include carbon steel, copper, and other alloys, each offering distinct properties that cater to different needs in fire protection systems.

4. Seamless Pipes in Fire Water Supply System Design

4.1 Pipe Sizing and Flow Requirements

The design of a fire water supply system involves careful consideration of pipe sizing and flow requirements. Seamless pipes contribute to efficient water flow due to their smooth interior surface, reducing friction losses. Engineers must calculate the required pipe diameter and layout to ensure an adequate water supply for firefighting activities.

4.2 Pressure Considerations

Pressure is a critical factor in fire water supply systems. Seamless pipes, known for their ability to withstand high pressures, play a vital role in maintaining the required pressure levels throughout the system. Proper pressure calculations, taking into account elevation changes and friction losses, are essential to ensure effective firefighting capabilities.

4.3 Integration with Fire Hydrants and Sprinkler Systems

Seamless pipes are seamlessly integrated into fire hydrant and sprinkler systems, which are essential components of fire protection infrastructure. The pipes connect these elements to the main water supply, ensuring a rapid and controlled release of water in the event of a fire.

5. Installation Techniques for Seamless Pipes in Fire Water Supply Systems

5.1 Proper Handling and Storage

The proper handling and storage of seamless pipes are critical to preventing damage and ensuring their structural integrity. Pipes should be stored in a dry, well-ventilated area, away from corrosive agents. Careful handling during transportation and installation helps avoid dents, scratches, or other forms of physical damage.

5.2 Welding and Joining Techniques

While seamless pipes do not have welded seams, certain components of a fire water supply system, such as fittings and connections, may require welding. It is crucial to follow industry standards and best practices for welding to maintain the overall integrity of the system. Welding should be carried out by certified professionals using appropriate techniques and materials.

5.3 Quality Assurance and Inspection

Quality assurance measures, including thorough inspection of seamless pipes before and after installation, are essential to identify any defects or irregularities. Non-destructive testing methods, such as ultrasonic testing and radiographic examination, can be employed to ensure the pipes meet the required standards and specifications.

6. Maintenance Practices for Seamless Pipes in Fire Water Supply Systems

6.1 Periodic Inspections

Regular inspections of the fire water supply system, including seamless pipes, should be conducted to identify any signs of wear, corrosion, or damage. Periodic inspections help detect issues early, allowing for timely repairs or replacements, thereby preventing potential failures during an emergency.

6.2 Corrosion Prevention Measures

Corrosion is a common concern in fire water supply systems, particularly in industrial environments. Implementing corrosion prevention measures, such as the application of protective coatings or cathodic protection, enhances the lifespan of seamless pipes and ensures their continued reliability.

6.3 Emergency Response Planning

An effective emergency response plan should be in place to address any unforeseen issues with the fire water supply system. This plan should include procedures for shutting off sections of the system, diverting water flow, and coordinating with emergency services to minimize the impact of a failure.

7. Case Studies: Successful Implementation of Seamless Pipes in Fire Water Supply Systems

7.1 Industrial Facilities

Several industrial facilities have successfully implemented fire water supply systems with seamless pipes to protect their assets and personnel. Case studies highlight the importance of proper material selection, system design, and maintenance practices in ensuring the reliability of these systems in high-risk environments.

7.2 Commercial Buildings

Commercial buildings, such as shopping malls and office complexes, rely on seamless pipes in their fire water supply systems to meet stringent safety standards. Case studies demonstrate the seamless integration of these pipes into the overall fire protection infrastructure of such structures.

7.3 Residential Areas

In residential areas, seamless pipes contribute to the effectiveness of fire hydrant systems and residential sprinkler systems. Case studies showcase how these pipes play a crucial role in safeguarding homes and communities from the devastating effects of fires.

8. Future Trends and Innovations in Seamless Pipes for Fire Water Supply Systems

8.1 Advanced Materials

Ongoing research and development in materials science may lead to the discovery of new alloys and coatings that further enhance the performance of seamless pipes in fire water supply systems. Advanced materials with improved corrosion resistance, strength, and durability could revolutionize the field.

8.2 Smart Monitoring and Maintenance

The integration of smart technologies for monitoring the condition of seamless pipes in real-time could become a future trend. Sensors and data analytics tools could provide insights into the health of the pipes, allowing for predictive maintenance and reducing the risk of unexpected failures.

8.3 Sustainable Practices

The adoption of sustainable practices in the manufacturing and use of seamless pipes is likely to gain prominence. This includes the use of recycled materials, energy-efficient manufacturing processes, and a focus on reducing the environmental impact of fire water supply systems.

9. Conclusion

Seamless pipes have proven to be indispensable in fire water supply systems, contributing to the efficiency, reliability, and safety of these critical infrastructure components. Their unique characteristics, such as strength, corrosion resistance, and smooth interior surfaces, make them well-suited for the demanding requirements of firefighting applications. Proper material selection, meticulous system design, and regular maintenance practices are essential to maximize the lifespan and performance of seamless pipes in fire protection scenarios. As technology advances and new innovations emerge, seamless pipes are likely to continue playing a pivotal role in safeguarding lives and property from the devastating impact of fires.

Read more: Din en 10220 seamless steel pipes

Eastern Steel Manufacturing Co.,Ltd not only improve product production and sales services, but also provide additional value-added services. As long as you need, we can complete your specific needs together.

Eastern Steel Manufacturing Co.,Ltd not only improve product production and sales services, but also provide additional value-added services. As long as you need, we can complete your specific needs together.