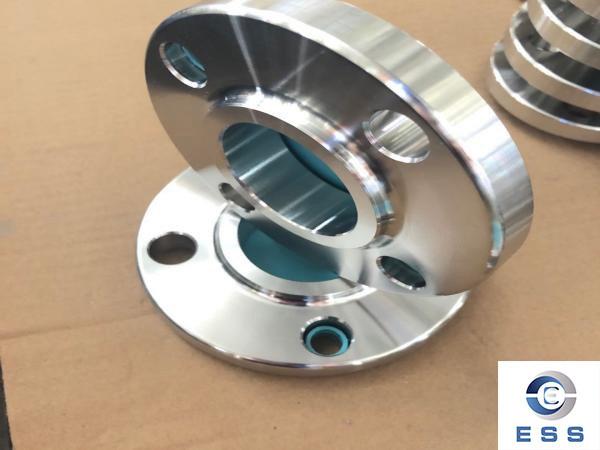

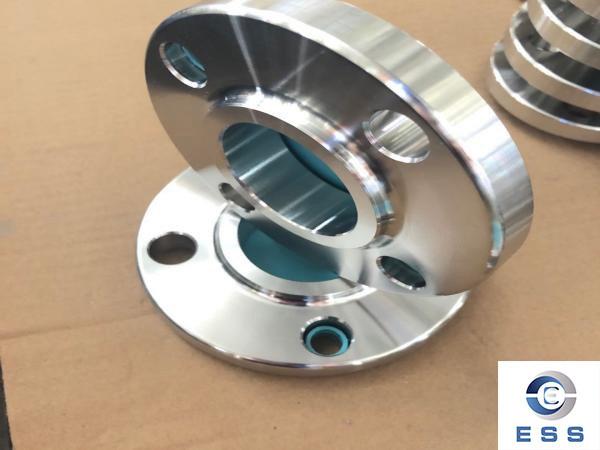

Advantages and disadvantages of

flange oxidation process

Introduction of flange

Flange oxidation process is a process commonly used to enhance the corrosion resistance, hardness and wear resistance of metal material surfaces. This process is a process of converting one or more substances into their oxidized forms by exposing substances to an oxidizing agent to produce a chemical reaction, thereby generating an oxide film on the surface of the metal material to improve its physical and chemical properties. The oxide film can not only improve the surface quality of the material and improve the corrosion resistance and oxidation resistance of the material, but also make the surface of the material have better electrical conductivity, thermal conductivity and optical properties. In industrial production, oxidation processes are widely used in various fields, such as metallurgy, chemical industry, electronics, medicine, etc.

Oxidation process

1. Pipe fitting clamping: Special clamps or spreaders should be designed according to the shape and size of the pipe fittings. The purpose is to leave sufficient gaps between the pipe fittings, and the pipe fittings cannot contact each other, so that each pipe fitting can be completely immersed in the oxidizing solution and oxidized.

2. Degreasing: The purpose is to remove oil stains on the surface of pipe fittings. After machining (blue and black is the last process), it is inevitable that no oil stain will be left on the surface of the pipe fittings, especially if anti-rust oil is used to prevent rust between processes. Any oil contamination will seriously affect the formation of ferric oxide, so it must be removed before it turns blue or black. .

3. Pickling: The purpose of pickling is to remove rust on the surface of pipe fittings. Because rust and rust spots will prevent the formation of a dense ferric oxide layer. Even if the pipe fittings are rust-free, they should still be pickled, because it can further remove oil stains, and pickling will increase the activation energy of molecules on the surface of the workpiece, which is conducive to oxidation in the next process and can generate a thicker iron tetroxide layer. .

The pickling solution is generally a sulfuric acid solution with a concentration of 10 to 15%, and the temperature is 70 to 80°C. The pipe fittings are immersed in the sulfuric acid solution for about 30 minutes. Steel parts with light corrosion can be immersed for 20 minutes. For those with severe corrosion, it is necessary to Soak for more than 40 minutes.

4. Oxidation: Oxidation is the main process of bluing and blackening. Whether the ferric oxide film is dense, smooth, and thick enough depends on the oxidation stage.

Advantage of flange oxidation process

1. Enhance corrosion resistance: An oxide film is formed on the surface of the material after flange oxidation treatment, and the contact between the material surface and the surrounding environment becomes thinner, thereby enhancing the corrosion resistance of the material.

2. Improve hardness: The hardness of the oxide film is relatively high, which can significantly improve the hardness and wear resistance of the material.

3. Improve surface electrical and electrochemical properties: The oxide film can improve the electrical and electrochemical properties of the material surface, such as increasing resistivity and electrochemical stability.

4. Improve the surface and performance of the material and expand the application scope of the material; for some materials that need to improve their surface properties, the oxidation process can improve them without changing the basic properties of the material.

Disadvantages of flange oxidation process

1. Affects size and shape: The generation of oxide film will increase the size and change the shape of the material. Especially in situations with high precision requirements, special processing is required to avoid size and shape deformation.

2. Restricted material types: Flange oxidation can only process metal materials that can generate oxide films, such as aluminum, magnesium, titanium and other materials. It is not effective for materials that are not easily oxidized.

3. The oxidation process may cause internal stress in the material, making it easy to form defects such as cracks; the oxidation process on some materials may reduce its strength, hardness and other properties.

4. Application areas

The flange oxidation process is widely used in aviation, automobile, electronics, machinery and other industries, such as aircraft casings, oxide layers of automobile engines, electronic component casings, etc.

Summarize

The flange oxidation process is an effective process for enhancing the surface properties of metal materials. The advantages include enhanced corrosion resistance, increased hardness, improved surface electrical and electrochemical properties, etc. However, the disadvantages include affecting the size and shape of the material, and is only applicable to Metal materials capable of producing oxide films. In practical applications, comprehensive considerations need to be made based on specific circumstances.

Eastern Steel Manufacturing Co.,Ltd not only improve product production and sales services, but also provide additional value-added services. As long as you need, we can complete your specific needs together.

Eastern Steel Manufacturing Co.,Ltd not only improve product production and sales services, but also provide additional value-added services. As long as you need, we can complete your specific needs together.