Causes of casing pipe deformation

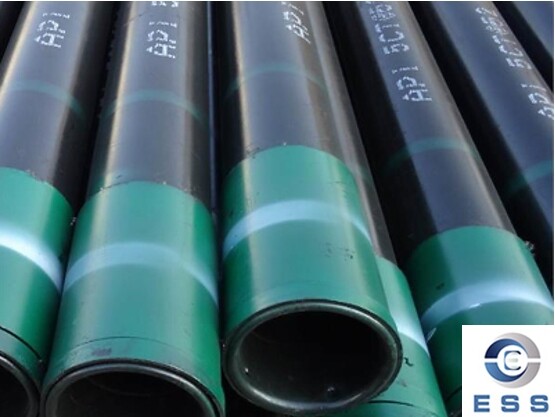

As an OCTG pipe, the

casing pipe is a tubular device used for protection, support or insulation, and

is widely used in construction, electrical, petroleum and other fields. There

are many reasons for casing pipe deformation, such as high temperature, high

pressure, wear, corrosion and other factors, which can easily cause casing pipe deformation. In addition,

there are the following common reasons:

1. Unreasonable design

If the casing pipe design does not match

the actual application environment, it is easy to cause premature wear,

deformation and other problems.

2. Improper use

During use, if the operation is not carried

out according to the instruction manual, it will also cause casing pipe

deformation.

3. Material factors

The material

quality of the casing pipe is uneven. If low-quality materials are used, it

is also easy to cause casing pipe deformation.

How to deal with casing pipe deformation

1. Replace the casing pipe

If the casing pipe is severely deformed and

cannot be repaired, it needs to be replaced. At this time, it should be noted

that the casing pipe that meets the actual use environment must be selected to

avoid deformation again.

2. Repair the casing pipe

If the deformation of the casing pipe is

not very serious, it can be handled by repairing the casing pipe. During the

repair process, the deformed part should be smoothed with a grinder or a

grinder, and then the casing pipe should be heat treated with a heater to

restore it to its normal shape. After the repair, the test should be carried

out to ensure that there is no problem with the casing pipe.

3. Enhance the wear resistance of the

casing pipe

In actual use, for easily worn casing

pipes, the wear resistance of the casing pipe can be improved by using

reinforced materials.

4. Strengthen maintenance

For casing pipes that are used for a long

time, regular inspections and maintenance should be carried out to find and

deal with problems in time. At the same time, lubrication, cleaning and other

work should be done to extend the service life of the casing pipe.

Conclusion

In summary, it is not difficult to deal

with casing pipe deformation. The key is to find and deal with problems in

time. For some key equipment, regular inspections and maintenance should be

carried out to ensure the normal operation of the machine and avoid machine

failures and production accidents.

Eastern Steel Manufacturing Co.,Ltd not only improve product production and sales services, but also provide additional value-added services. As long as you need, we can complete your specific needs together.

Eastern Steel Manufacturing Co.,Ltd not only improve product production and sales services, but also provide additional value-added services. As long as you need, we can complete your specific needs together.