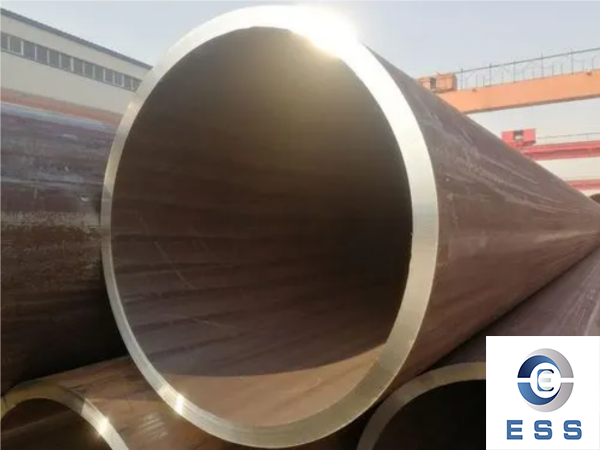

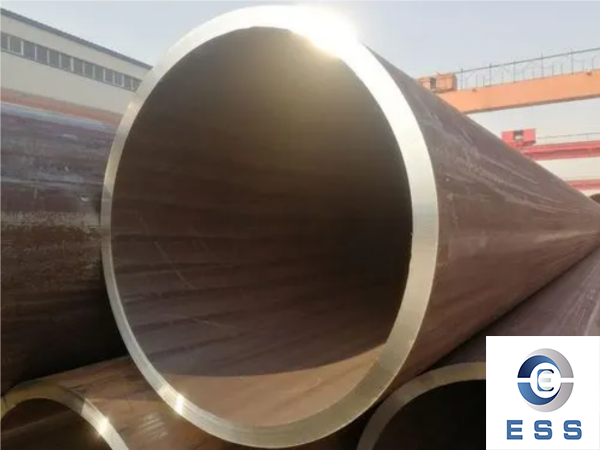

What are the factors that affect the durability of LSAW steel pipes?

Longitudinal Submerged Arc Welded (LSAW) steel pipes are widely used in various industries due to their exceptional strength and durability. However, their performance and longevity can be influenced by a range of factors. This article aims to delve into the key elements that impact the durability of LSAW steel pipes, exploring the production process, material quality, environmental factors, and maintenance practices that can affect their lifespan and overall performance.

1.Introduction:

Longitudinal Submerged Arc Welded (LSAW) steel pipes have become a vital component of modern infrastructure, playing a crucial role in the transportation of oil, gas, water, and other fluids. Their strength, ductility, and corrosion resistance make them a preferred choice in industries such as oil and gas, water supply, and construction. However, the durability of these pipes is critical to ensure the smooth functioning and safety of the systems they are employed in. This article will delve into the factors that impact the durability of LSAW steel pipes, enabling us to better understand how to optimize their lifespan and performance.

2.LSAW Steel Pipe Production Process:

The production process of LSAW steel pipes significantly influences their durability. The key steps involved in manufacturing LSAW pipes include plate preparation, edge milling, pre-bending, forming, welding, ultrasonic inspection, seam heat treatment, sizing, straightening, cutting, and end beveling.

2.1 Plate Preparation:

The quality of the raw steel plates used in the production process has a direct impact on the durability of the LSAW steel pipes. High-quality steel plates with suitable chemical composition, mechanical properties, and cleanliness should be selected to ensure the pipes meet the required standards and performance expectations.

2.2 Edge Milling and Pre-bending:

Proper edge milling and pre-bending of the plates help ensure precise alignment during the welding process. Accurate alignment is essential to prevent weld defects and ensure the integrity of the longitudinal seam.

2.3 Welding:

The welding process significantly affects the durability of LSAW steel pipes. Advanced welding techniques, precise control of welding parameters, and high-quality weld materials are crucial to producing strong and defect-free welds.

2.4 Heat Treatment:

The heat treatment of the longitudinal seam is essential to relieve welding-induced stresses and improve the pipe's mechanical properties. Adequate heat treatment ensures the pipe has the desired strength and toughness.

3.Material Quality:

The choice of steel material used in LSAW pipes plays a vital role in determining their durability. Several factors influence the material quality:

3.1 Chemical Composition:

The chemical composition of the steel should be carefully controlled to achieve the desired mechanical properties, corrosion resistance, and weldability. Proper alloying elements, such as carbon, manganese, silicon, and trace elements, influence the pipe's strength and resistance to environmental factors.

3.2 Mechanical Properties:

The mechanical properties, including yield strength, tensile strength, and elongation, must meet the specified requirements to ensure the pipe can withstand internal and external loads throughout its service life.

3.3 Microstructure:

The microstructure of the steel, particularly the grain size and distribution, affects its mechanical properties and resistance to fatigue and fracture.

3.4 Inclusions and Defects:

The presence of inclusions, voids, or other defects in the steel can significantly reduce the pipe's durability. Quality control during production is essential to minimize these issues.

4.Environmental Factors:

The external environment can have a substantial impact on the durability of LSAW steel pipes:

4.1 Corrosion:

Corrosion is a major threat to the longevity of steel pipes, especially in environments where they are exposed to moisture, chemicals, or other corrosive substances. Proper coating and cathodic protection are essential to mitigate corrosion.

4.2 Temperature and Weather Conditions:

Extreme temperatures, cyclic thermal loads, and exposure to harsh weather conditions can lead to thermal fatigue and degradation of the pipe's material properties.

4.3 Soil and Groundwater Conditions:

In buried pipelines, the soil composition and groundwater chemistry can influence the rate of corrosion and affect the overall durability of the pipes.

5.Maintenance Practices:

Regular maintenance and inspections are critical to ensure the long-term performance of LSAW steel pipes:

5.1 Corrosion Protection:

Regular inspection and maintenance of protective coatings and cathodic protection systems help prevent and address corrosion issues.

5.2 Monitoring:

Continuous monitoring of pipeline performance, including internal pressure, temperature, and stress, can help detect potential problems and avoid catastrophic failures.

5.3 Cleaning and Debris Removal:

Periodic cleaning and debris removal inside the pipes prevent the accumulation of harmful substances and potential blockages.

5.4 Repairs and Rehabilitation:

Promptly addressing any defects, damages, or abnormalities discovered during inspections is vital to maintaining the structural integrity of the pipes.

Conclusion:

LSAW steel pipes are indispensable components of critical infrastructure, and their durability is paramount to ensure the efficient and safe transportation of fluids. Understanding the various factors that influence their longevity, such as production processes, material quality, environmental conditions, and maintenance practices, is crucial in optimizing their performance and extending their service life. By implementing appropriate measures and adopting best practices, we can enhance the durability and reliability of LSAW steel pipes, ultimately contributing to the sustainability and success of our industrial systems.

Eastern Steel Manufacturing Co.,Ltd not only improve product production and sales services, but also provide additional value-added services. As long as you need, we can complete your specific needs together.

Eastern Steel Manufacturing Co.,Ltd not only improve product production and sales services, but also provide additional value-added services. As long as you need, we can complete your specific needs together.