The Advantages of Stainless Steel Seamless Pipe

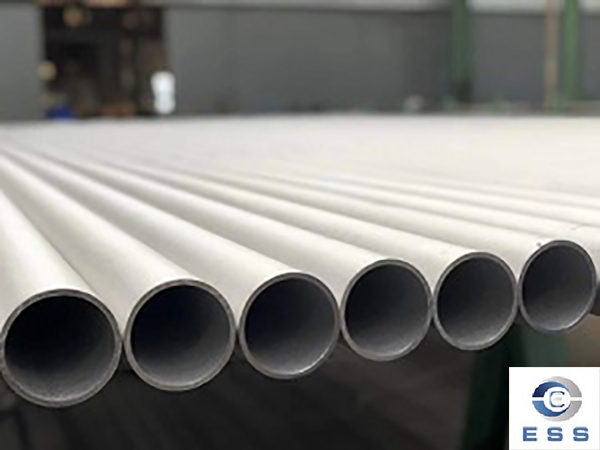

Stainless steel seamless pipe has been widely used in a variety of industries due to its numerous advantages. Stainless steel is an alloy of iron, carbon, and other metals, with a minimum of 10.5% chromium content. The chromium in the steel forms a passive layer of chromium oxide on the surface of the steel, which helps to prevent corrosion and rusting. Stainless steel seamless pipes are made from solid round steel billets that are heated and pierced to form a hollow tube. This process produces a pipe with no seams or joints, resulting in a more uniform and stronger product than other types of pipes. This essay will discuss the advantages of stainless steel seamless pipes in various industries.

Advantages of Stainless Steel Seamless Pipes

1、Corrosion Resistance

One of the primary advantages of stainless steel seamless pipes is their high resistance to corrosion. Stainless steel is highly resistant to rust and corrosion due to the presence of chromium. The chromium oxide layer that forms on the surface of the steel acts as a protective barrier, preventing the steel from coming into contact with oxygen and other corrosive materials.

Stainless steel seamless pipes are commonly used in harsh environments where other materials would corrode quickly. They are often used in the chemical, oil and gas, and petrochemical industries, where they are exposed to highly corrosive substances. Stainless steel seamless pipes are also used in marine environments, where they are exposed to saltwater and other corrosive elements.

2、Strength and Durability

Stainless steel seamless pipes are highly durable and resistant to wear and tear. They are made from solid round steel billets, which are heated and pierced to form a hollow tube. This process produces a pipe with no seams or joints, resulting in a more uniform and stronger product than other types of pipes.

Stainless steel seamless pipes are also able to withstand high temperatures and pressure, making them suitable for use in high-temperature and high-pressure applications. They are commonly used in the oil and gas industry, where they are exposed to high temperatures and pressures.

3、Hygienic Properties

Stainless steel seamless pipes are easy to clean and have excellent hygienic properties, making them suitable for use in industries that require high levels of cleanliness and sanitation. They are commonly used in the food and beverage industry, where they are used to transport liquids and gases.

Stainless steel is non-porous and has a smooth surface, making it difficult for bacteria and other microorganisms to grow. This makes stainless steel seamless pipes ideal for use in applications where cleanliness is critical, such as in hospitals, laboratories, and clean rooms.

4、Aesthetic Appeal

Stainless steel seamless pipes have an aesthetically pleasing appearance and are often used in architectural and design applications. They can be polished to a high shine, giving them a sleek and modern look.

Stainless steel seamless pipes are commonly used in the construction of buildings, bridges, and other structures. They are also used in the automotive industry, where they are used for exhaust systems and other components.

5、Cost-Effective

Stainless steel seamless pipes are a cost-effective solution for many applications. While they may be more expensive than other materials, such as carbon steel or plastic, their durability and longevity make them a more cost-effective option in the long run.

Stainless steel seamless pipes require less maintenance than other materials, which reduces maintenance costs over time. They also have a longer lifespan than other materials, reducing the need for frequent replacements.

Applications of Stainless Steel Seamless Pipes

1、Oil and Gas Industry

The oil and gas industry is one of the largest users of stainless steel seamless pipes. Stainless steel seamless pipes are used in a variety of applications, including oil and gas transportation, drilling, and refining.

Stainless steel seamless pipes are highly resistant to corrosion and can withstand high temperatures and pressures , making them ideal for use in the oil and gas industry. They are used in offshore platforms, pipelines, and refineries, where they are exposed to harsh environments and corrosive substances.

2、Chemical Industry

Stainless steel seamless pipes are commonly used in the chemical industry, where they are used to transport and process chemicals and other corrosive materials. Stainless steel seamless pipes are highly resistant to corrosion and can withstand high temperatures and pressures, making them ideal for use in the chemical industry.

They are used in chemical processing plants, where they are used to transport acids, alkalis, and other corrosive materials. Stainless steel seamless pipes are also used in the production of chemicals, such as fertilizers, pesticides, and pharmaceuticals.

3、Food and Beverage Industry

Stainless steel seamless pipes are widely used in the food and beverage industry, where they are used to transport liquids and gases. Stainless steel is non-porous and has a smooth surface, making it easy to clean and highly resistant to bacteria and other microorganisms.

Stainless steel seamless pipes are used in food processing plants, breweries, and dairy farms, where they are used to transport milk, beer, and other liquids. They are also used in the production of soft drinks and bottled water.

4、Automotive Industry

Stainless steel seamless pipes are commonly used in the automotive industry, where they are used for exhaust systems and other components. Stainless steel is highly resistant to corrosion and can withstand high temperatures and pressures, making it ideal for use in exhaust systems.

Stainless steel seamless pipes are also used in the production of automotive components, such as fuel lines and brake lines. They are also used in the production of high-performance racing cars, where they are used to transport fuel and other fluids.

5、Architectural and Design Applications

Stainless steel seamless pipes are often used in architectural and design applications. They have an aesthetically pleasing appearance and can be polished to a high shine, giving them a sleek and modern look.

Stainless steel seamless pipes are used in the construction of buildings, bridges, and other structures. They are also used in the production of furniture, lighting fixtures, and other design elements.

Conclusion

Stainless steel seamless pipes have numerous advantages, making them a popular choice in a variety of industries. They are highly resistant to corrosion, have excellent hygienic properties, and are cost-effective in the long run. Stainless steel seamless pipes are used in a variety of applications, including the oil and gas industry, chemical industry, food and beverage industry, automotive industry, and architectural and design applications.

As industries continue to evolve and require higher levels of performance and durability, stainless steel seamless pipes will continue to be a popular choice. With their strength, durability, and resistance to corrosion, stainless steel seamless pipes are an excellent choice for applications that require high levels of performance and reliability.

Eastern Steel Manufacturing Co.,Ltd not only improve product production and sales services, but also provide additional value-added services. As long as you need, we can complete your specific needs together.

Eastern Steel Manufacturing Co.,Ltd not only improve product production and sales services, but also provide additional value-added services. As long as you need, we can complete your specific needs together.