Sub-temperature quenching process of OCTG casing

Special oil pipes are mainly used for drilling oil and gas wells and transporting oil and gas. It includes oil drilling pipe, oil casing and oil pumping pipe. Oil drill pipe is mainly used to connect drill collars and drill bits and transmit drilling power. Oil casing is mainly used to support the well wall during the drilling process and after well completion to ensure the drilling process and the normal operation of the entire oil well after completion. The pumping pipe mainly transports oil and gas from the bottom of the oil well to the surface.

Oil casing is the lifeline to maintain the operation of oil wells. Due to different geological conditions and complex stress conditions downhole, tension, compression, bending and torsion stresses act comprehensively on the pipe body, which places higher requirements on the quality of the casing itself. Once the casing itself is damaged for some reason, the entire well may be reduced in production or even scrapped. According to the strength of the steel itself, casing can be divided into different steel grades, namely J55, K55, N80, L80, C90, T95, P110, Q125, V150, etc. Different well conditions and well depths require different steel grades. In corrosive environments, the casing itself is also required to have corrosion resistance. In places with complex geological conditions, the casing is also required to have anti-collapse properties.

Subtemperature quenching process

27MnCrV is a new steel grade for the production of TP110T steel grade oil pipe casings. The conventional steel grades for the production of TP110T steel grade oil pipe casings are 29CrMo44 and 26CrMo4. Compared with the latter two, 27MnCrV contains less Mo element, which can greatly reduce production costs. However, after using the normal austenitizing quenching process to produce 27MnCrV, there is obvious high-temperature temper brittleness, resulting in low impact toughness and instability.

Two methods are usually used to solve such problems:

One is to use rapid cooling after tempering to avoid high temperature brittleness and obtain toughness.

The second is the sub-temperature quenching method, which effectively improves harmful elements and impurities and improves toughness through incomplete austenitization of steel.

The first method has relatively strict requirements on heat treatment equipment and requires additional costs. The AC1=736℃ and AC3=810℃ of 27MnCrV steel, the heating temperature during sub-temperature quenching is selected between 740-810℃. The heating temperature for sub-temperature quenching is 780°C, and the holding time for quenching and heating is 15 minutes; the temperature for tempering after quenching is 630°C, and the tempering and heating holding time is 50 minutes. Since sub-temperature quenching is heated in the α + γ two-phase region, quenching is performed while retaining part of the undissolved ferrite state, and the toughness is improved while maintaining high strength. At the same time, low-temperature quenching is lower than the conventional temperature, which reduces the quenching stress and thereby reduces the quenching deformation. This ensures the smooth operation of heat treatment production and provides good raw materials for subsequent wire processing.

This process has been applied in the factory. The quality assurance data shows that the yield strength Rt0.6 of the heat-treated steel pipe is 820-860MPa, the tensile strength Rm is 910-940MPa, the impact toughness Akv is between 65-85J, and the damage resistance is 100% qualified. . The data shows that 27MnCrV steel pipe is already a very high-quality high-grade petroleum casing. On the other hand, it also shows that the sub-temperature quenching process is an excellent method to avoid high-temperature brittleness in the production of steel products.

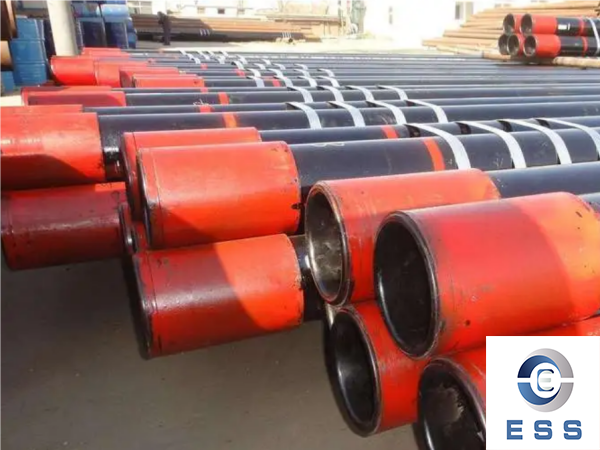

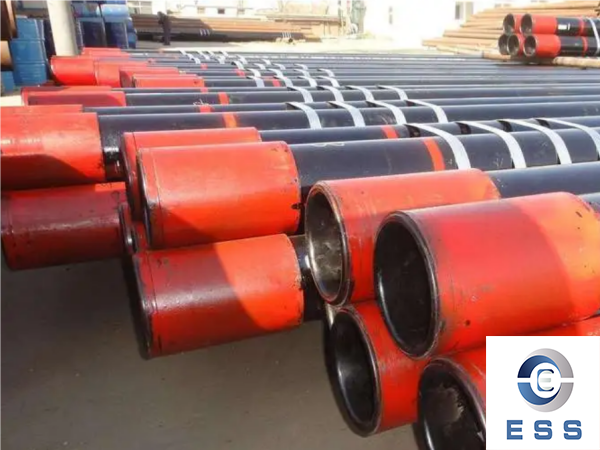

Uses of oil casing

Oil casing is a large-diameter pipe that plays a role in fixing the walls or wellbore of oil and natural gas wells. The casing is inserted into the wellbore and fixed with cement to help the wellbore separate the rock formations and prevent the wellbore from collapsing, while ensuring the circulation of drilling mud to facilitate drilling and mining. Steel grades of oil casing: H40, J55, K55, N80, L80, C90, T95, P110, Q125, V150, etc. Casing end processing forms: short round thread, long round thread, partial trapezoidal thread, special buckle, etc. It is used in oil well drilling to support the well wall during the drilling process and after well completion to ensure the drilling process and the normal operation of the entire oil well after completion. The important position of oil pipes The petroleum industry is an industry that uses a large number of oil pipes. Oil pipes occupy a very important position in the petroleum industry:

1. Oil pipes consume a lot of money and cost a lot, so there is huge potential to save expenses and reduce costs. The consumption of oil well pipes can be calculated based on the annual drilling footage. According to the specific conditions of our country, roughly 62kg of oil well pipe is required for every 1m of drilling, including 48kg of casing and 10kg of tubing. Drill pipe 3kg, drill collar 0.5kg;

2. The mechanics and environmental behavior of oil pipes have an important impact on the petroleum industry’s adoption of advanced technologies and increased production and efficiency;

3. The failure of oil pipes causes huge losses, and their safety, reliability and service life are of great concern to the petroleum industry.

Read more: The causes of OCTG casing stuck or What are the grades of OCTG casing?

Eastern Steel Manufacturing Co.,Ltd not only improve product production and sales services, but also provide additional value-added services. As long as you need, we can complete your specific needs together.

Eastern Steel Manufacturing Co.,Ltd not only improve product production and sales services, but also provide additional value-added services. As long as you need, we can complete your specific needs together.