There are two main forms of common steel pipes, namely welded pipes and seamless steel pipes. Because the cost of welded steel pipe is obviously lower than seamless steel pipe, so some businesses in order to seek more economic benefits, welding steel pipe processing, and then pass it off as seamless steel pipe, and then into the market for sale, resulting in market chaos. From the appearance of the welded steel pipe processing can not be effectively identified, once in the process of engineering construction, should use seamless steel pipe but the use of welded steel pipe, will lead to gas or liquid leakage, serious also prone to explosion, so we must identify the welded steel pipe and seamless steel pipe, so as to ensure the quality of the project.

Welding steel pipe is generally steel belt or steel plate under the action of external force, make it into a round or square, and then weld the surface of the joint, thus forming a welded steel pipe. The commonly used processes are arc welding, high frequency or low frequency, cold rolling, etc., but the use of these processes will lead to steel pipe weld. At present, according to the shape of the weld, it can be divided into straight seam steel pipe and spiral welded steel pipe, but the two processes are different.

The spiral steel pipe is welded by submerged arc welding, which has the advantages of high welding efficiency and less dust. For high-frequency or low-frequency welding, it is mainly based on the principle of electromagnetic induction. Due to the proximity and turbine thermal effects of AC charge in the conductor, the steel at the edge of the weld can be fused and the welding can be finally completed.

Seamless steel pipe is mainly made of solid tube billet or steel ingot by perforation, and through hot rolling, cold rolling, cold drawing and other processing, seamless steel pipe is formed. Since seamless steel tubes contain a midhole section, this midhole section can be used as a conduit for fluid transfer.

Method of distinguishing seamless steel pipe and welded pipe

There are four main ways to distinguish welded steel pipe from seamless steel pipe:

1. The metallographic method

Metallographic method is one of the main methods to distinguish welded steel pipe from seamless steel pipe. There is no welding material added to the high-frequency resistance welded steel pipe, so the weld seams in the welded steel pipe are very narrow. If the method of coarse grinding and then corrosion is adopted, the weld seams cannot be clearly seen.

Once the high frequency resistance welded steel pipe is welded without heat treatment, the weld microstructure will be substantially different from the parent steel pipe material. At this time, the metallurgical method can be used to distinguish the welded steel pipe from the seamless steel pipe.

On the steel tube in the process of identifying, need to take the length and width in the welds are 40 mm small kind, carries on the coarse grinding, fine grinding and polishing processing, and then put it in metallographic microscope, when observed ferrite and westergren, mother material and weld area organization, can accurately identify welded steel pipe and seamless steel tube

2. The corrosion method

In using corrosion method to identify in the process of welded steel pipe and seamless steel tube, should be in the processing of welded steel pipe welds in grinding processing, after completion of polishing should be able to see the trace of grinding, and then in the weld with end face of sand paper burnish, treatment of 5% nitric acid alcohol solution and end face, if there is a obvious weld, can prove this steel pipe is welded steel pipe. There is no significant difference in the end surface of seamless steel pipe after corrosion.

3. Identify welded steel pipe and seamless steel pipe according to the process

In the process of distinguishing welded steel pipe from seamless steel pipe according to technology, welded steel pipe is welded according to cold rolling, extrusion and other processes. In addition, spiral pipe welding and straight seam pipe welding will be formed when steel pipe is welded by high-frequency and low-frequency arc welding and resistance welding. It can form round steel pipe, square steel pipe, oval steel pipe, triangle steel pipe, hexagonal steel pipe, diamond steel pipe, octagonal steel pipe, and even more complex steel pipe.

In short, different processes will form different shapes of steel pipes, so that welded steel pipes and seamless steel pipes can be clearly distinguished.

However, according to the process of identifying seamless steel pipe, mainly according to the hot rolling and cold rolling treatment to identify, and seamless steel pipe is mainly in two forms, respectively, hot rolled seamless steel pipe and cold rolled seamless steel pipe. Hot rolled seamless steel pipe is formed by perforation, rolling and other processes, especially the large diameter and thickness of seamless steel pipe are welded by this process; The cold-drawn tube is formed by cold drawing of the tube blank. The strength of the material is lower, but the surface and internal control surface are smooth.

4. Distinguish welded steel pipe and seamless steel pipe according to the classification of use

The welded steel pipe has higher bending and torsional strength and more load-bearing capacity, so it is generally widely used in the manufacturing of mechanical parts. For example, oil drill pipes, automobile drive shafts, bicycle racks and steel scaffolds used in construction are all made of welded steel pipes. Seamless steel tubes, however, can be used as conduits for fluid delivery because of their hollow cross sections and the absence of jointed strips of steel around them.

For example, it can be used as a pipeline to transport oil, natural gas, gas, water, etc. In addition, the bending strength of seamless steel tube is relatively small, so it is generally widely used in low and medium pressure boiler superheated steam tube, boiling water tube and locomotive boiler with superheated steam tube. In short, through the classification of use, can clearly distinguish welded steel pipe and seamless steel pipe.

In order to ensure that the construction quality is higher, it is necessary to distinguish between welded steel pipe and seamless steel pipe, and then use the appropriate steel pipe for construction. In the process of identifying welded steel pipe and seamless steel pipe, metallographic method and corrosion method can be used, by observing the tissue and weld, so as to check the weld, and finally accurately identify it. At the same time, the two kinds of steel pipes can be distinguished according to their performance and use, and then a reasonable steel pipe can be selected for construction.

seamless vs welded pipe

Performance of welded steel tubes

The welded steel pipe has the following properties because it is processed by high-frequency welding and cold rolling.

First, the heat preservation function is good. The heat loss degree of welded steel pipe is relatively small, only 25%, which is not only conducive to transportation, but also reduces the cost.

Second, with waterproof and corrosion resistance, in the process of engineering construction, there is no need to set a separate pipe trench, just the steel pipe directly buried underground or underwater, so as to reduce the difficulty of engineering construction.

Third, it has impact resistance. Even in the low temperature environment, the steel pipe will not be damaged, so its performance has certain advantages.

Performance of seamless steel tubes

Because the metal material of seamless steel pipe has greater tensile strength, so its damage resistance is stronger, and it has a hollow channel, so it can effectively transport fluid, it is its transport ability is strong, so the corrosion resistance of seamless steel pipe is higher than that of welded steel pipe, and its stiffness is relatively large. Therefore, the more load the seamless steel tube carries, the more it can be widely used in projects with higher construction requirements.

Principle

1. Macroscopic identification

When the prepared steel pipe sample is observed by naked eye or using a magnifying glass ≤10 times, welding phenomenon is found, that is, complete welding morphological characteristics of weld zone, fusion zone and base metal zone, and identified as welded steel pipe. If there is no welding phenomenon, it is considered as seamless steel pipe.

2. Microscopic identification

if macroscopic identification is difficult, use a use a metallographic microscope for microscopic identification, adjust the optical path and magnification of the metallographic microscope, start from a lower multiple, observe the whole cross section, found that welding signs are difficult to confirm, use a higher multiple for further analysis. The welded steel pipe or seamless steel pipe is identified according to the presence of welding structure characteristics.

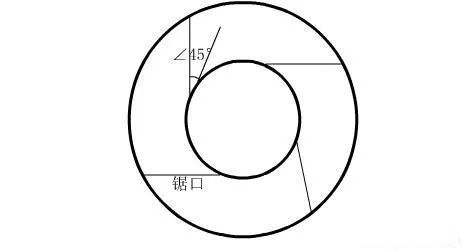

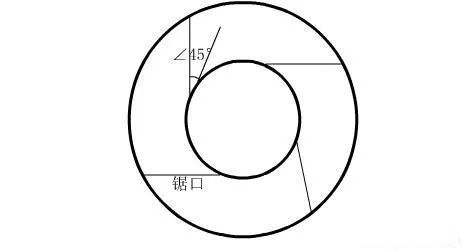

According to GB/T 13298, the steel pipe is cut in the complete cross section by cold cutting, and the heat affected zone is removed by hot cutting. Steel pipe as far as possible the total cross-section grinding polishing, such as a larger diameter steel pipe grinding polishing, not all section can be broken into several sections on cross section, curf width is not more than 2 mm (it is recommended to use the cutting), curf and point the tangent of the Angle is not more than 45 ° Angle, so as to ensure no residual weld, curf and steel tube schematic diagram, as shown in figure 1.

Organization display method

1. Etching method

The erosive agent is recommended to use 3% ~ 5% nitric acid - ethanol solution, and other metallographic display agents can also be selected. Soak or smear the prepared reagent evenly on the surface to be examined in a ventilated place at room temperature. Etching time depends on steel type and reagent. After corrosion, rinse with water, rinse with ethanol, and dry quickly with hot air.

2. Chemical deposition membrane method

During film formation, the sample should be immersed in the reagent in a ventilated place, and the color of the sample should be observed. When the surface of the sample changes from yellow to blue, the sample should be immediately removed, rinsed with water, rinsed with ethanol, and quickly dried with hot air.

3. Identification method

magnification

10×, 50×, 100×, 200×, 500×, etc., according to the size of the test sample and the clarity of the microstructure, to be able to see the tissue state, type and whether the welding shall be subject to.

Macro to identify

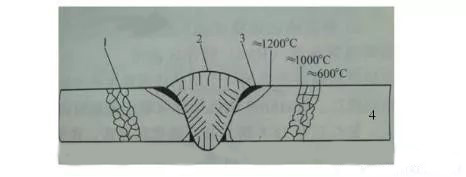

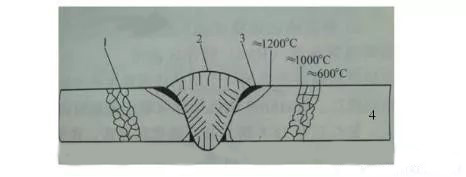

After the above sample preparation, a magnifying glass ≤10 times can be used to observe, as shown in FIG. 2, the middle of which is the macroscopic welding morphology.

1 - the base area

2 - the weld area

3 - the fusion zone

4. Microscopic identification

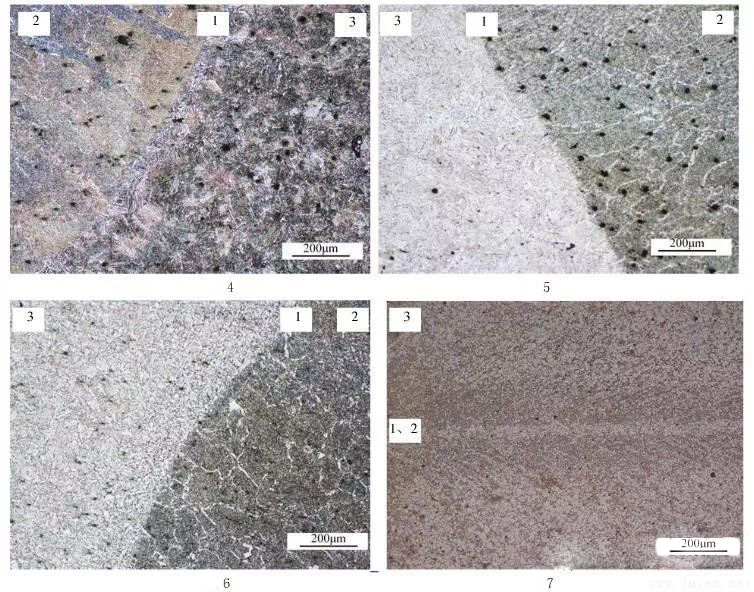

If no weld seams are found macroscopically, they can be examined using a microscope. Without welding microstructure, hot rolled banded microstructure, twin microstructure and equiaxed grain have continuity. The microstructure of welded steel pipe has obvious characteristics. Stainless steel generally has sensitization zone, weld zone, fusion zone, base metal four areas, see Figure 3.

1 - sensitizing area

2 - the weld area

3 - the fusion zone

4 - the base area

5. Welding structure characteristics

Reference picture of metallographic structure: Welded structure with obvious fusion zone. There is cooling crystalline structure at the weld, and the crystallization is generally directional. The microstructure of the heat affected zone near the weld base metal is characterized by carbide precipitation or coarse microstructure.

6. Welding structure of carbon steel

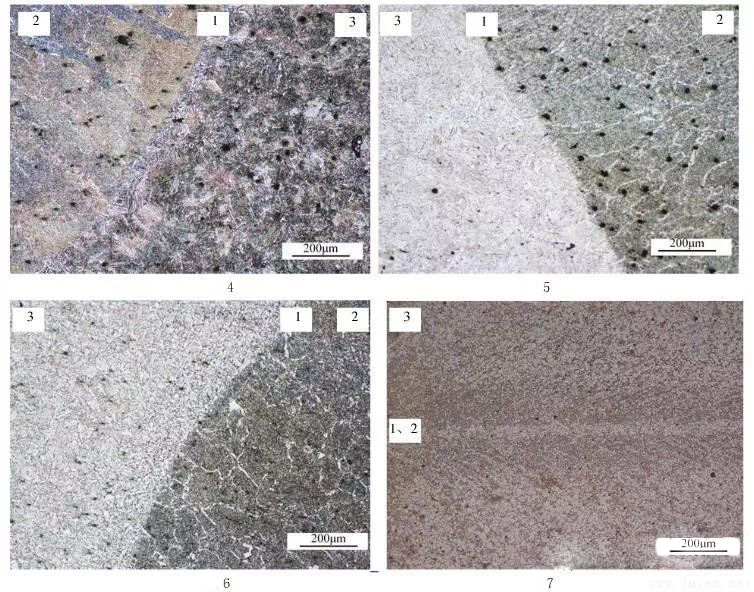

The magnification is 100 times, refer to Figure 4-7;

1 - the fusion zone

2 - the weld area

3 - Heat affected zone

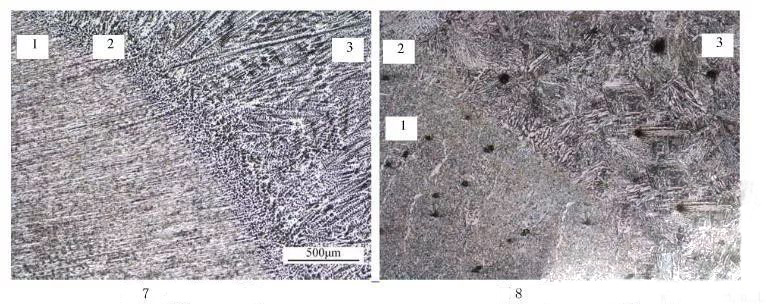

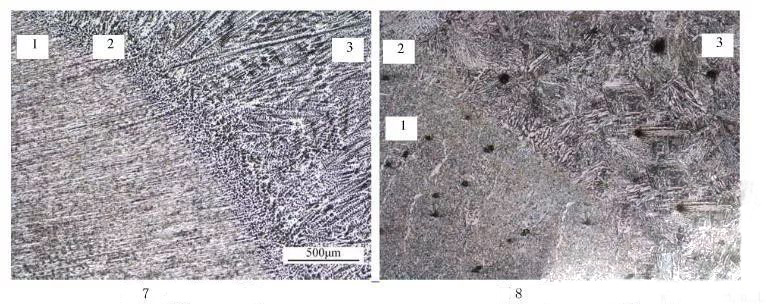

7. Stainless steel welding structure

The magnification is 50x, refer to Figure 7-8.

1 - the weld area

2 - the fusion zone

3 - the base area

Read more : Differences between ERW vs seamless pipes in classification or Latest Top 6 Seamless Steel Pipe Manufacturers in China

Eastern Steel Manufacturing Co.,Ltd not only improve product production and sales services, but also provide additional value-added services. As long as you need, we can complete your specific needs together.

Eastern Steel Manufacturing Co.,Ltd not only improve product production and sales services, but also provide additional value-added services. As long as you need, we can complete your specific needs together.