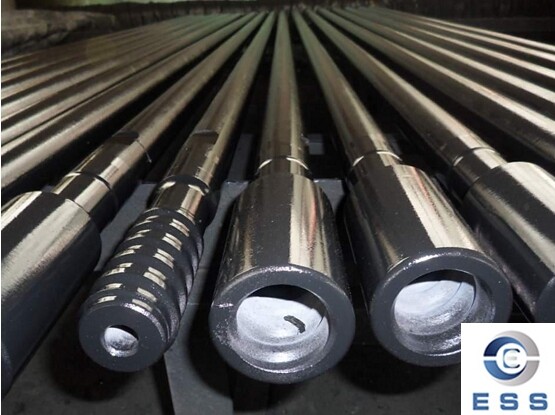

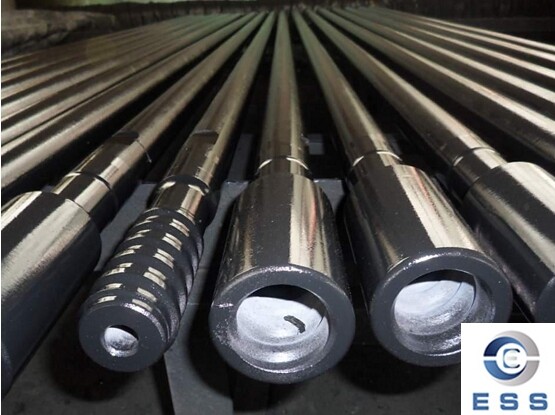

Drill pipe is a tool used for oil drilling and is part of the OCTG pipe. Its

diameter and model are one of the most important parameters in drilling. The

larger the diameter, the greater the drilling efficiency and load-bearing

capacity.

Common drill pipe diameter standards

1. Imperial drill pipe diameter standard

The imperial drill pipe diameter standard

is a common one. Its unit is inches (inch). Common diameters are: 2 3/8 inches,

2 7/8 inches, 3 1/2 inches, 4 inches, 4 1/2 inches, etc.

2. Metric drill pipe diameter standard

The metric drill pipe diameter standard

refers to the standard with diameter in millimeters (mm). The more common

diameters are: 60mm, 73mm, 89mm, 102mm, 114mm, etc.

Common drill pipe models and their

parameters

The drill pipe model is also an important

parameter in drilling. Different models of drill pipes are suitable for

different drilling needs. The following are several common drill pipe models

and their parameters (taking the imperial system as an example):

|

Model

|

Diameter

(in.)

|

Capacity

(10,000 lbs.)

|

Application

|

|

NC26

|

2

3/8

|

69

|

Shallow

well

|

|

NC31

|

2

7/8

|

106

|

Shallow

well

|

|

NC38

|

3

1/2

|

159

|

Middle

well

|

|

NC46

|

4

1/8

|

259

|

Middle

well

|

|

NC50

|

4

1/2

|

291

|

Deep

well

|

|

5

|

5

|

380

|

Deep

well

|

|

5

1/2FH

|

5

1/2

|

517

|

Ultra-deep

well

|

From the table above, it can be seen that

the diameters and parameters of different models of drill pipes are different.

In drilling, it is necessary to select the appropriate drill pipe model

according to actual needs.

How to choose the right drill pipe model

The following factors need to be considered

when choosing the right drill pipe model:

1. Well depth and well diameter

This is the first factor to consider when

choosing a drill pipe. Generally speaking, the greater the well depth and well

diameter, the thicker the drill pipe required, and its bearing capacity should

be enhanced accordingly. Therefore, for deep wells or large-diameter wells,

drill pipes with larger diameters and higher strength should be selected.

2. Drilling geological conditions

Different geological conditions have

different requirements for drill pipes. In softer formations, thinner drill

pipes can be selected to save costs and improve efficiency; in hard or complex

geological conditions, drill pipes with larger diameters, stronger materials,

and higher bearing capacity need to be selected to ensure the stability and

safety of drilling.

3. Drill bit and wellbore size

The size of the drill bit and wellbore

should match the drill pipe. The diameter of the drill pipe should be slightly

smaller than the diameter of the wellbore to ensure that the drill pipe can be

lifted and rotated smoothly in the wellbore. At the same time, the length of

the drill pipe should also be selected according to actual needs to adapt to

different drilling depths and working environments.

4. Drilling operation conditions

Harsh construction conditions (such as high

temperature, high pressure, high humidity, etc.) will affect the performance of

the drill pipe. Under these conditions, it is necessary to select a drill pipe

with higher strength, better corrosion resistance and longer service life.

5. Drill pipe material and performance

Drill pipes are usually made of

high-strength alloy steel to ensure their reliability under high pressure, high

temperature and harsh environments. Different materials and performance

characteristics will affect the service life and drilling efficiency of the

drill pipe. Therefore, when selecting a drill pipe, it is necessary to

comprehensively consider factors such as its material, strength, wear

resistance, and corrosion resistance. In addition to the above key factors, it

is also necessary to consider factors such as the connection method of the

drill pipe (such as API threaded connection or non-API threaded connection),

price, and supply channels.

Summary

In summary, choosing the right drill pipe

specification model requires comprehensive consideration of multiple factors,

and weighing and selecting according to actual needs and conditions. It is

recommended to consult professionals or refer to relevant standards and

specifications when selecting drill pipes to ensure that the selected drill

pipes can meet actual drilling needs and have good performance and reliability.

Read more: Size of Drill Pipe or How Many Types of Drill Pipe Threads Are There?

Eastern Steel Manufacturing Co.,Ltd not only improve product production and sales services, but also provide additional value-added services. As long as you need, we can complete your specific needs together.

Eastern Steel Manufacturing Co.,Ltd not only improve product production and sales services, but also provide additional value-added services. As long as you need, we can complete your specific needs together.