What are the maintenance requirements of erw pipes?

Introduction:

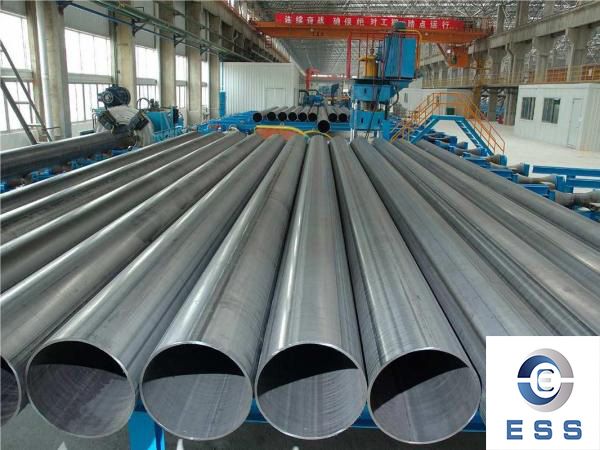

ERW (Electric Resistance Welded) pipes are widely used in various industries for the transportation of fluids, such as water, oil, and gas. These pipes are known for their durability, cost-effectiveness, and versatility. However, like any other infrastructure, ERW pipes require regular maintenance to ensure their optimal performance and longevity. In this article, we will explore the maintenance requirements for ERW pipes and provide useful tips for keeping them in good condition.

Understanding ERW Pipes:

Before delving into the maintenance requirements, it's crucial to understand what ERW pipes are and their construction. ERW pipes are created by rolling metal coils through a series of rollers, which shape the coil into a cylindrical tube. Electric current is then passed through the edges of the tube to create a fusion weld, resulting in a high-strength pipe.

Importance of Maintenance:

Regular maintenance of ERW pipes is essential for several reasons. Firstly, it helps identify and prevent potential issues before they escalate into major problems, minimizing the risk of pipe failures, leaks, or bursts. Secondly, proper maintenance ensures the pipes continue to operate efficiently, reducing energy consumption and improving overall system performance. Lastly, well-maintained ERW pipes have a longer lifespan, which translates into cost savings for the industry.

Visual Inspection:

Visual inspection is one of the primary maintenance tasks for ERW pipes. Regularly inspecting the exterior of the pipes can help identify signs of damage, corrosion, or leaks. Look for any visible cracks, dents, or discoloration on the pipe's surface. Additionally, check for signs of leakage such as water stains or wet spots. If any issues are detected, they should be addressed promptly to prevent further damage.

Corrosion Protection:

Corrosion is a common problem for metal pipes, including ERW pipes. To prevent corrosion, it is essential to apply appropriate protective measures. This can include the use of protective coatings or paints that act as a barrier between the metal surface and the surrounding environment. Regular inspection of the coatings and touch-ups when necessary can help maintain their effectiveness.

Cleaning and Flushing:

ERW pipes can accumulate debris, sediment, or mineral deposits over time, affecting their performance and efficiency. Regular cleaning and flushing of the pipes are necessary to remove such build-up. Flushing with clean water or appropriate cleaning agents can help dislodge and remove any accumulated materials, ensuring smooth flow and reducing the risk of clogs or blockages.

Monitoring Water Quality:

For ERW pipes used in water supply systems, monitoring water quality is crucial. Poor water quality with high levels of impurities or corrosive elements can accelerate pipe deterioration. Regular testing of water samples can help identify any issues, allowing for timely corrective actions. Water treatment methods, such as filtration or chemical treatments, may be required to maintain the water quality and preserve the pipes' integrity.

Maintaining Pipe Supports:

Proper support and alignment of ERW pipes are vital for their longevity. Ensure that the pipes are adequately supported at regular intervals along their length. This prevents excessive stress or sagging, which can lead to pipe deformation or failure. Inspect the pipe supports for any signs of damage or wear and replace or repair them as necessary.

Cathodic Protection:

Cathodic protection is an electrochemical technique used to protect metallic structures, including ERW pipes, from corrosion. It involves the installation of sacrificial anodes or impressed current systems to counteract the corrosive process. Regular inspection and maintenance of cathodic protection systems are essential to ensure their effectiveness. Anode replacement, voltage monitoring, and system testing should be performed as per the manufacturer's recommendations.

Monitoring Pressure and Temperature:

Monitoring pressure and temperature is crucial for maintaining the integrity of ERW pipes. Excessive pressure or temperature fluctuations can lead to pipe failure. Regularly inspect pressure gauges, valves, and temperature sensors to ensure they are functioning correctly. Calibrate and replace these instruments when necessary to maintain accurate readings.

Professional Inspection and Testing:

While regular visual inspection and maintenance can help identify many issues, it is also recommended to have periodic professional inspection and testing of ERW pipes. Trained technicians can perform non-destructive testing methods such as ultrasonic testing, magnetic particle testing, or radiography to detect hidden defects, cracks, or weaknesses that may not be visible during routine inspections. These tests provide valuable insights into the pipes' condition and allow for proactive maintenance measures.

Conclusion:

Maintaining ERW pipes is vital for their optimal performance, longevity, and safety. Regular visual inspection, corrosion protection, cleaning and flushing, monitoring water quality, maintaining pipe supports, cathodic protection, monitoring pressure and temperature, and periodic professional inspection are all important maintenance requirements for ERW pipes. By following these maintenance practices, industries can ensure the reliability and efficiency of their ERW pipe systems, saving both time and money in the long run.

Eastern Steel Manufacturing Co.,Ltd not only improve product production and sales services, but also provide additional value-added services. As long as you need, we can complete your specific needs together.

Eastern Steel Manufacturing Co.,Ltd not only improve product production and sales services, but also provide additional value-added services. As long as you need, we can complete your specific needs together.