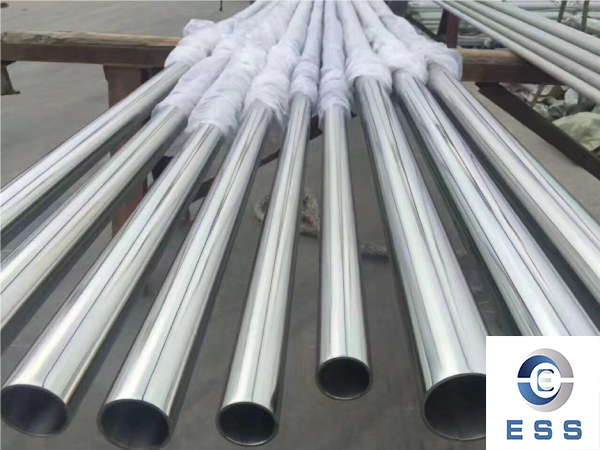

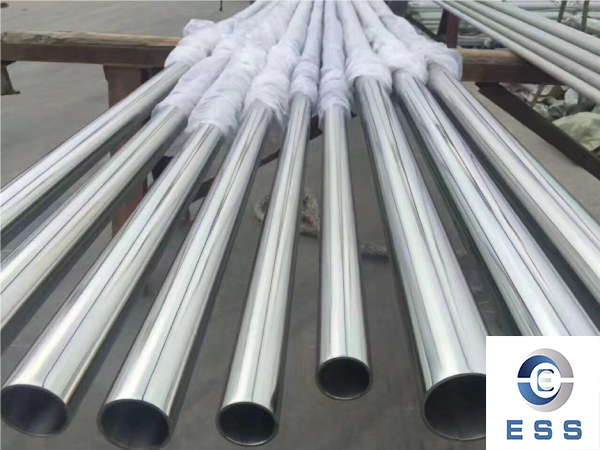

Solution to Cold Work Hardening of Stainless Steel Seamless Pipe

Md(30/50) is the temperature at which 50% martensite is formed after 30% cold deformation. The lower the martensite transformation point Md(30/50), the less likely martensite will be induced during cold working deformation, and the smaller the degree of cold work hardening, the more favorable it is for deep drawing. Among them, the effect of Ni content on the mutagenic martensitic transformation point is the most obvious. The higher the Ni content, the lower the martensitic transformation point, and the less hardened the material during cold deformation.

The principle of cold work hardening

The cold hardening phenomenon of stainless steel is mainly caused by two reasons: one is work hardening caused by the increase of dislocations; the other is work hardening caused by structural transformation (transformation of austenite to martensite). For 06Cr19Ni10(304) steel, there is no microstructure transformation during processing and deformation, and the cold work hardening phenomenon is all caused by the increase of dislocations. 06Cr19Ni10 (304) steel has two kinds of hardening phenomena in the cold deformation process, and the hardening caused by the transformation of the structure is the main one. This is also the cold hardening phenomenon of austenitic stainless steel than that of ferritic stainless steel. The work hardening coefficient (value of n) is large.

The elimination of work hardening generally has the following methods:

1. Recrystallization annealing: a heat treatment process in which the cold deformed metal is heated above the recrystallization temperature, kept for a certain period of time and then cooled to cause recrystallization. Recrystallization annealing is used in production to eliminate work hardening of processed products, improve plasticity, and residual stress can be completely eliminated. Recrystallization annealing is sometimes performed in the middle of cold deformation processing, which is to restore plasticity for continued processing.

2. Solution annealing (a common method for chromium-nickel stainless steel): that is, carbide solution annealing, a method of heating the finished part to above 1010 degrees Celsius to remove carbide precipitation (that is, carbon escaping from the stainless steel solid solution) After that, it is rapidly cooled, usually quenched with water, and the carbides contained are returned to the stainless steel solid solution. Solution annealing can be applied to a series of alloy steel and stainless steel components. For the solution treatment of 300 series stainless steel castings Can produce a uniform microstructure without carbide impurities. Solution annealing of precipitation hardening alloy castings and forgings can produce softer microstructures.

304 stainless steel pipe cold working strengthening

Cold working (such as cold rolling, cold drawing) can improve the strength of steel pipes, while austenitic 304 stainless steel pipes cannot be strengthened by heat treatment, but can be strengthened by cold working deformation (cold work hardening, deformation strengthening), which will increase the strength and plasticity. decline. After austenitic stainless steel is strengthened by cold working deformation, there is a large processing stress. The existence of this stress increases the sensitivity of stress corrosion and affects the dimensional stability when used in a stress corrosion environment. In order to reduce stress, stress relief treatment can be used. Generally, it is heated to 280°C-400°C and kept for 2h-3h, then air-cooled or slowly cooled. The stress relief treatment can not only reduce the stress of the 304 stainless steel pipe, but also improve the hardness, strength and elastic limit without changing the elongation.

First of all, attention should be paid to the heating temperature of solution treatment of stainless steel products. In the material standard of austenitic stainless steel, the range of heating temperature for solution treatment is relatively wide. During the actual heat treatment production, the specific composition, content, use environment, and possible Reasonably choose the best heating temperature based on failure form and other factors. However, it should be noted that the melting heating temperature is too high, because the solution treatment heating temperature is too high, which may cause the grain growth of the material whose grain has been refined after forging, and the coarsening of the grain will cause some adverse consequences.

Secondly, attention should be paid to the effect of stabilization treatment on the properties of the solid solution state. Austenitic 304 stainless steel pipes containing stabilizing elements will tend to decline in mechanical properties when they are stabilized after solution heat treatment. Both plasticity and toughness have this phenomenon. The reason for the decrease in strength may be that during the stabilization treatment, the strong carbide-forming element titanium combines with more carbon to form TiC, which reduces the strengthening degree of carbon in the austenite solid solution, and TiC will also accumulate during heating and heat preservation. Growing up, this also has an effect on strength.

Thirdly, the heating temperature of the stabilization treatment should not be too high, generally between 850°C and 930°C. 304 stainless steel pipes are not suitable for multiple solution treatments, because multiple solution heating will cause grain growth and adversely affect the properties of the material. At the same time, attention should be paid to pollution during processing. Once contaminated, measures to eliminate pollution should be taken.

The above is the cold processing strengthening and stress relief treatment of 304 stainless steel pipes. Cold processing will increase the strength and decrease the plasticity, and the steel pipe will have greater processing stress after cold processing. In the presence of stress, heat treatment is required and heated to 280°C to 400°C for 2h to 3h, then air-cooled or slowly cooled. In addition, it is necessary to pay attention to the heating temperature of the solution treatment, the influence of the stabilization treatment on the performance of the solid solution state and the heating temperature of the stabilization treatment should not be too high.

Eastern Steel Manufacturing Co.,Ltd not only improve product production and sales services, but also provide additional value-added services. As long as you need, we can complete your specific needs together.

Eastern Steel Manufacturing Co.,Ltd not only improve product production and sales services, but also provide additional value-added services. As long as you need, we can complete your specific needs together.