Maintenance methods of welded pipe

Welded steel pipe, also known as welded pipe, is a steel pipe made by welding steel plates or steel strips after curling and forming. The production process of welded steel pipe is simple, the production efficiency is high, there are many varieties and specifications, and the equipment investment is low, but the general strength is lower than that of

seamless steel pipe. Correct use:

During the use of welded pipes, correct use is very important because it involves service life and safety. The following are some precautions for the correct use of welded pipes:

1.Installation: Welded pipes should be installed correctly to avoid excessive stretching or compression. Appropriate fasteners and supports should be used during installation to ensure that the pipes are not damaged by external forces.

2.Bending: When welded pipes need to be bent during installation, special pipe bending machines or manual pipe bending tools should be used. Manual bending may cause deformation or damage to the pipes.

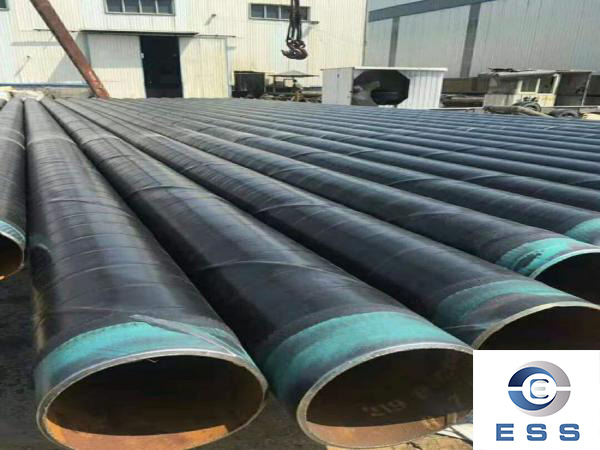

3.Anti-corrosion: When welded pipes are used in corrosive environments, appropriate anti-corrosion measures should be taken, such as coating anti-corrosion materials or

using corrosion-resistant welded pipes.

4.Temperature: When welded pipes are used in high temperature environments, appropriate insulation measures should be taken to prevent overheating and damage to the pipes.

5. Pressure: When the welded pipe is used in a high-pressure environment, the strength and sealing of the pipe should be checked regularly to ensure that it meets the design requirements.

As we all know, the service life of an item is directly related to its maintenance, and welded pipes are no exception. In order to extend its service life, we must pay attention to the daily maintenance and maintenance of welded pipes. Here is a brief introduction to the maintenance of welded pipes.

1.Cleaning and grinding: If the welded pipe is damaged, it should be polished, especially the scratches and splashes caused by contact with carbon steel parts, and the damage caused by cutting slag must be carefully and thoroughly cleaned and polished.

2.Mechanical polishing: Use appropriate polishing tools for polishing, require uniform treatment, and avoid over-throwing and re-scratching.

3.Degreasing and dust removal: Before pickling and passivation, the welded pipe must be cleaned of oil, scale, dust and other debris according to the welded pipe process.

4.Water sandblasting: According to different processing requirements, different micro glass beads and different process parameters should be selected, and over-spraying should be avoided.

5.Pickling and passivation: The pickling and passivation of the welded pipe must be strictly passivated according to the process requirements.

6.Cleaning and drying: After pickling and passivation, neutralization, rinsing and drying should be carried out strictly according to the process to completely remove the residual acid.

7.

Protection: After the surface treatment of the welded pipe is completed, protection should be done to avoid secondary contamination by personnel touching and oil, dust and other debris.

Daily maintenance of the welded pipe can not only greatly extend its service life, but also greatly improve its efficiency and safety in daily use. Therefore, everyone must remember the above methods and remember to perform daily maintenance on the welded pipe.

Eastern Steel Manufacturing Co.,Ltd not only improve product production and sales services, but also provide additional value-added services. As long as you need, we can complete your specific needs together.

Eastern Steel Manufacturing Co.,Ltd not only improve product production and sales services, but also provide additional value-added services. As long as you need, we can complete your specific needs together.