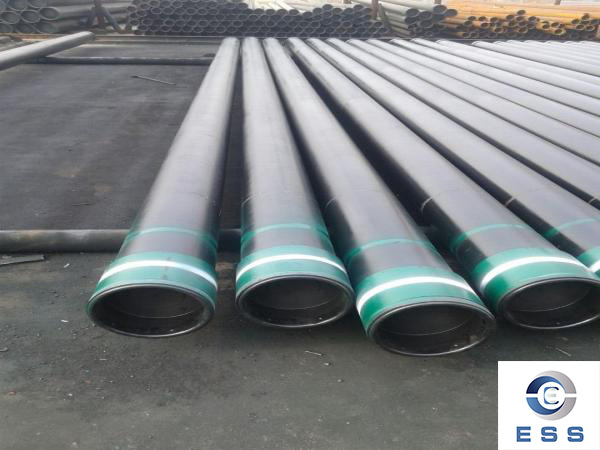

Casings for water supply systems

What is casing?

Casing refers to the connecting pipe used between two pipes of different specifications,such as seamless pipe.Casing can be divided into rubber casings, steel casings and other materials. In water supply and drainage projects, casings mainly play three roles: First, to protect the pipeline from external impact and damage; Second, to enhance the pressure-bearing capacity and stability of the pipeline; Third, to make the pipeline connection closer and improve the sealing of the pipeline performance.

Where can casing be used?

1. Steel casing application

Steel casing is suitable for the connection and conversion of some large-diameter water supply steel pipe, and is widely used in municipal, industrial, petrochemical and energy fields. For example, the municipal drainage pipeline connects two drainage pipelines of different specifications, and the connection between the gas pipeline and the gas meter can be connected with steel casing, which is convenient and fast.

(1) Sewage treatment

Sewage treatment plants are one of the areas where steel casings are widely used. In sewage treatment systems, steel casings are mostly used to connect to main pipes and water outlets to ensure that the entire system can operate normally. At the same time, steel casings can also be used in sludge transportation and sludge concentration. In sewage treatment plants, steel casings are usually used to connect mixers, dosing equipment, flow meters and other equipment.

(2) Building drainage system

In building drainage systems, steel casings are widely used in sewers, underground pipes and ventilation ducts. Due to the strong anti-corrosion performance of steel casing, it can not only resist the corrosion of rainwater, but also resist the corrosion of groundwater and chemical substances. In building drainage systems, steel casings are mostly used in large commercial buildings and public buildings, such as shopping malls, stadiums, hospitals, etc.

(3) Municipal road drainage system

In municipal road drainage systems, steel casings are mainly used in percolation wells and stormwater drainage systems. These steel casings can effectively prevent water accumulation on roads from causing traffic jams and casualties, and ensure the smooth drainage of rainwater. In municipal road drainage systems, steel casings are mainly used in drainage systems and tunnel projects on urban roads and squares.

In the above three fields, the application scope of steel casing is also expanding. For example, in urban forest green belt drainage systems, steel casings can connect natural gas pipelines, heating pipelines and other facilities, thereby realizing an intelligent and diversified urban drainage system.

In short, steel casing is an indispensable component of modern water supply and drainage systems, and its wide range of applications and excellent performance have attracted more and more attention and applications.

2.Rubber casing application

Rubber casing is suitable for fire water supply, household water supply and some small-diameter pipeline systems. Rubber casing has the characteristics of good sealing, high pressure resistance, oil corrosion resistance, and good earthquake resistance. It is widely used in fire water supply systems and ventilation pipes of household tap water systems to ensure the normal operation of the water supply system.

(1) Agricultural irrigation

In agricultural production, irrigation is a very important link. Water transmission rubber pipe has become one of the commonly used pipe materials in agricultural irrigation due to its flexibility and pressure resistance. During the irrigation process, water delivery rubber pipes can be used to transport water sources, such as river water, lake water, etc. It can also be used with irrigation equipment, such as drip irrigation, sprinkler irrigation, spray irrigation, etc. The material of water delivery rubber pipes has good weather resistance and corrosion resistance, can adapt to different water source environments and climate conditions, and greatly improves the efficiency of agricultural production.

(2) Urban water supply

In daily life in the city, water is essential. The water transmission rubber pipe is also an indispensable part of the urban water supply system. Water delivery rubber pipes not only have a larger diameter, but also have a higher pressure-bearing capacity and can withstand high-intensity water supply pressure. At the same time, the sealing performance of the water delivery rubber pipe is also very good, avoiding leakage problems during the water supply process. In urban water supply systems, rubber water pipes are usually buried underground, so they are required to have a long service life and strong corrosion resistance.

(3) Construction site

Rubber water pipes are also common on construction sites. During the construction process, many materials need to be transported, such as concrete, cement, sand, etc. Water conveying rubber pipes can play a role in transporting materials on construction sites. Water delivery rubber pipes come in different diameters and thicknesses and can be customized as needed to adapt to different building material delivery needs. In construction sites, water delivery rubber pipes need to have high wear resistance and pressure resistance to ensure that they can be used for a long time without damage.

How to choose the casing correctly

The correct selection of casing specifications and materials is key to ensuring the normal operation of the water supply system. The selection should be based on the material, diameter, medium, etc. of the pipeline. Generally, in terms of household water supply, rubber casings can meet the needs; in industry and municipal aspects, steel casings or rubber casings can be used depending on the specific circumstances. Especially for occasions with high corrosion resistance requirements, rubber casings are more suitable. Advantage.

In short, choosing the appropriate pipe connection method is crucial to ensure the normal operation of the water supply system. When actually selecting casing, the selection needs to be based on specific circumstances.

Eastern Steel Manufacturing Co.,Ltd not only improve product production and sales services, but also provide additional value-added services. As long as you need, we can complete your specific needs together.

Eastern Steel Manufacturing Co.,Ltd not only improve product production and sales services, but also provide additional value-added services. As long as you need, we can complete your specific needs together.