About Us

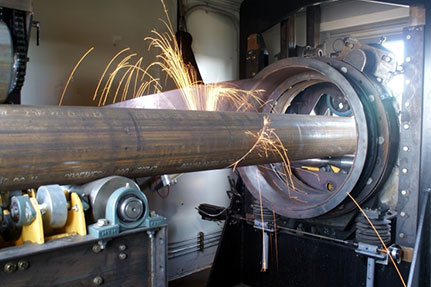

Eastern Steel Manufacturing Co.,Ltd is a leading manufacturer and distributor of seamless steel pipe, welded steel pipe, OCTG products and fittings. We supply first-step processing, semi-finished parts and finished parts to help our clients meet fabrication requirements beyond their capacity or to improve operations by moving forward the pre-production processing.

Eastern Steel Manufacturing Co.,Ltd not only improve product production and sales services, but also provide additional value-added services. As long as you need, we can complete your specific needs together.

Eastern Steel Manufacturing Co.,Ltd not only improve product production and sales services, but also provide additional value-added services. As long as you need, we can complete your specific needs together.