¿Qué son las tuberías de acero dulce?

Como su nombre indica, los tubos de acero dulce (o tubos MS) son tubos de acero con un contenido de carbono bajo. En general, se diferencian de los tubos de acero al carbono sin costura. Los tubos de acero dulce se refieren a tubos de acero con un contenido de carbono inferior al 0,3 %. Los tubos de acero dulce sin costura pertenecen a uno de ellos. Además de los tubos de acero generales, los tubos de acero para calderas de baja y media presión, los tubos de acero para calderas de alta presión, los tubos de acero aleado, los tubos de acero inoxidable, los tubos de craqueo de petróleo y otros tubos de acero, los tubos de acero dulce también incluyen los tubos de acero al carbono de pared delgada, los tubos de acero aleado de pared delgada, los tubos de acero inoxidable de pared delgada y los tubos de acero conformados.

El acero bajo en carbono también se denomina acero dulce debido a su baja resistencia, dureza y blandura. Incluye la mayoría de los aceros estructurales al carbono comunes y algunos aceros estructurales al carbono de alta calidad, la mayoría de los cuales se utilizan para piezas estructurales de ingeniería sin tratamiento térmico, y algunos se utilizan para piezas mecánicas que requieren resistencia al desgaste después de la carburación y otros tratamientos térmicos. El acero dulce con un contenido de carbono de entre el 0,10 % y el 0,30 % es fácil de procesar en diversas aplicaciones, como forjado, soldadura y corte, y se utiliza a menudo en cadenas, remaches, pernos, ejes, etc.

1. Proceso de producción

La producción de tubos de acero dulce incluye principalmente los siguientes pasos: preparación de la materia prima → conformado → tratamiento térmico → tratamiento superficial.

Preparación de la materia prima: Las principales materias primas para la producción de tubos de acero dulce son el mineral de hierro, la chatarra de acero y los elementos de aleación. Estas materias primas se convierten en acero fundido mediante procesos de fundición y siderurgia.

Conformado: El acero fundido se cuela o lamina en palanquillas de acero, que posteriormente se procesan en formas tubulares mediante laminación en caliente o en frío.

Tratamiento térmico: Para mejorar el rendimiento de los tubos de acero dulce, generalmente se requiere un tratamiento térmico. Este tratamiento puede mejorar la microestructura del tubo de acero y sus propiedades mecánicas.

Tratamiento superficial: Antes de salir de fábrica, los tubos de acero dulce suelen someterse a un tratamiento superficial para mejorar su resistencia a la corrosión y su estética. Los métodos comunes de tratamiento de superficies incluyen la pulverización y el galvanizado.

2. Normas comunes

Los parámetros de las tuberías de acero dulce varían significativamente según las distintas normas nacionales. A continuación, se presenta una comparación de las normas principales:

|

Norma

|

Contenido máximo de carbono

|

Resistencia a la tracción (MPa)

|

Aplicaciones principales

|

|

ASTM A53

|

0.25%

|

330-500

|

Tuberías de presión, uso estructural

|

|

GB/T 3091

|

0.20%

|

315-490

|

Tuberías de agua y gas, andamios

|

|

JIS G3444

|

0.23%

|

300-470

|

Componentes estructurales mecánicos

|

Nota: La norma ASTM A53 Grado B tiene un mayor requisito de límite elástico (≥240 MPa) y es adecuada para aplicaciones de alta presión.

3. Dimensiones

Las tuberías de acero dulce suelen tener un diámetro interior de entre 3 mm y 15 mm. Los diámetros exteriores varían desde un mínimo de 0,406 pulgadas hasta un máximo de 6,5 pulgadas. Consulte siempre la

tabla de tamaños de tubos de acero dulce para determinar el tamaño de tubo adecuado para su aplicación.

4. Composición química

La

composición química de las tuberías de acero dulce suele incluir:

Carbono: 0,05-0,25 %

Silicio: 0,10-0,35 %

Manganeso: 0,30-1,60 %

Fósforo: ≤ 0,045 %

Azufre: ≤ 0,050 %

Cobre: 0,20-0,55 %

Cromo: ≤ 0,30 %

Níquel: ≤ 0,30 %

5. Propiedades mecánicas

Temperatura de transición de fase (valor aproximado): Ac1 = 735 °C, Ac3 = 855 °C, Ar3 = 835 °C, Ar1 = 680 °C

Temperatura de normalización especificada: 920 ~ 950 °C, refrigeración por aire fuera del horno. Dureza 131~156HBS.

Especificaciones para el tratamiento de reblandecimiento de piezas prensadas en frío: Temperatura de 700~720 °C, tiempo de mantenimiento de 8~15 h, y posteriormente, a una velocidad de enfriamiento de 50~100 °C/h, la temperatura se reduce con el horno a ≤550~600 °C, enfriándose con aire. La dureza antes del tratamiento es ≤143HBS y la dureza después del reblandecimiento es ≤131HBS.

Temperatura de temple especificada: 910 °C ± 10 °C, enfriamiento con salmuera de NaCl al 10 %.

Límite elástico medido: fy = 245 MPa, módulo elástico: E = 206 Gpa, coeficiente de Poisson: ν = 0,3.

La resistencia al corte es de 275 a 392 MPa, la resistencia a la tracción de 253 a 500 MPa, el límite elástico de 275 MPa y el alargamiento del 25 %.

La temperatura de recocido es de tan solo 600 a 650 grados y el tiempo de mantenimiento es de 1 a 2 h.

6. Tensión admisible

Tensión admisible del acero dulce a 225 °C: (16-36 mm) entre 111 y 124 MPa; (6-16 mm) entre 117 y 131 MPa.

Tensión admisible del acero dulce a 100 °C: 108 MPa

Propiedades de las tuberías de acero dulce

Las tuberías de acero dulce se caracterizan por su gran dureza, buena tenacidad, resistencia a altas temperaturas y excelente resistencia al impacto. Su superficie es compacta y ofrece numerosas ventajas. Incluso se pueden galvanizar cuando se requiere protección adicional contra la corrosión. Su rápida velocidad de conformado, alto rendimiento y no daña el recubrimiento permiten fabricarlas en diversas secciones transversales para satisfacer las necesidades de las condiciones de uso.

1. Buena plasticidad y tenacidad

Las tuberías MS soportan una mayor deformación bajo tensión, lo que reduce el riesgo de fractura.

2. Fáciles de procesar

Las tuberías MS presentan buena soldabilidad, son aptas para diversos métodos de procesamiento y conformado y cumplen con diferentes requisitos de diseño.

3. Menor coste

En comparación con las tuberías de acero de alta aleación, las tuberías MS tienen menores costes de producción, lo que las hace adecuadas para aplicaciones a gran escala.

4. Menor resistencia

Las tuberías MS no son tan resistentes como las de acero con alto contenido de carbono y pueden no ser adecuadas para aplicaciones con cargas pesadas.

5. Resistencia moderada a la corrosión

Aunque las tuberías MS tienen cierto grado de resistencia a la corrosión, aún requieren tratamiento superficial en entornos hostiles.

Aplicación de las tuberías de acero dulce

Las tuberías de acero dulce son una herramienta esencial en muchos sectores de la construcción, incluyendo aplicaciones industriales, proyectos de transporte e incluso obras de arquitectura.

Según la cantidad de carbono, el hierro se suele dividir en acero con alto contenido de carbono, acero con contenido medio de carbono y acero dulce. Cuanto mayor sea el contenido de carbono, más duro será el hierro, menor será su tenacidad y más fácil será de romper. El acero dulce generalmente se lamina en acero angular, acero de canal, vigas en I, tubos de acero, flejes de acero o placas de acero, y se utiliza para fabricar diversos componentes de construcción, contenedores, cajas, hornos y maquinaria agrícola.

Al mismo tiempo, las tuberías de acero dulce también son una herramienta importante en muchos campos.

1. Industria de la construcción

Las tuberías de acero dulce se utilizan comúnmente en los componentes de soporte de las estructuras de edificios, proporcionando una excelente resistencia y estabilidad. En los edificios modernos de gran altura, se utilizan ampliamente en estructuras de armazón, escaleras y barandillas.

2. Fabricación de maquinaria

En la industria de fabricación de maquinaria, las tuberías de acero dulce se utilizan para fabricar diversas piezas mecánicas, como ejes, varillas y soportes. Estas piezas requieren un cierto nivel de resistencia y tenacidad, que las tuberías de acero dulce cumplen a la perfección.

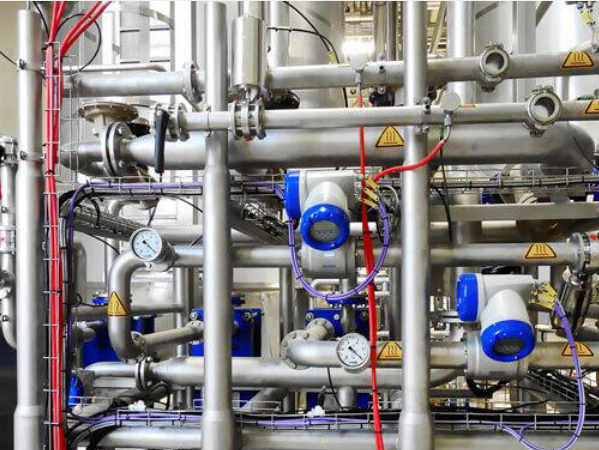

3. Industria petroquímica

Las tuberías de acero dulce también tienen importantes aplicaciones en la industria petrolera y química, principalmente para el transporte de líquidos y gases. Gracias a su buena resistencia a la corrosión y soldabilidad, las tuberías de acero dulce mantienen una buena estabilidad en entornos de alta temperatura y alta presión.

4. Transporte

Las tuberías de acero dulce también se utilizan ampliamente en el sector del transporte, como en la fabricación de armazones y componentes estructurales para automóviles, trenes y barcos. Estas aplicaciones requieren materiales con buena resistencia y tenacidad para soportar entornos externos en constante cambio.

¿Cuál es la diferencia entre el acero con alto contenido de carbono y las tuberías de acero dulce?

1. Diferencia en tenacidad

La estructura recocida del acero dulce se compone de ferrita y una pequeña cantidad de perlita, lo que le confiere baja resistencia y dureza, y buena plasticidad y tenacidad. Por lo tanto, presenta buena conformabilidad en frío y puede conformarse en frío mediante rizado, doblado, estampado y otros métodos.

Tras un tratamiento térmico adecuado o un endurecimiento por estirado en frío, el acero con alto contenido de carbono presenta alta resistencia y dureza, altos límites elásticos y de fatiga, y un rendimiento de corte aceptable, pero deficientes en cuanto a rendimiento de soldadura y capacidad de deformación plástica en frío.

2. Diferencias de aplicación

El acero dulce presenta buena soldabilidad. El acero dulce con un contenido de carbono de entre el 0,10 % y el 0,30 % se adapta fácilmente a diversos procesos, como forjado, soldadura y corte, y se utiliza a menudo para fabricar cadenas, remaches, pernos, ejes, etc. El acero con alto contenido de carbono se utiliza principalmente para fabricar resortes y piezas resistentes al desgaste. El acero al carbono para herramientas es un acero con alto contenido de carbono que prácticamente no incorpora elementos de aleación. También es un acero para herramientas de bajo costo, buena trabajabilidad en frío y en caliente, y una amplia gama de aplicaciones.

3. Contenido de carbono diferente

El acero dulce es un acero al carbono con un contenido de carbono inferior al 0,25 %, que presenta baja resistencia y dureza, buena plasticidad y tenacidad. El acero con alto contenido de carbono, a menudo llamado acero para herramientas, tiene un contenido de carbono que oscila entre el 0,60 % y el 1,70 %, con alta resistencia y dureza, altos límites elásticos y de fatiga, un rendimiento de corte aceptable, pero un rendimiento de soldadura deficiente y una capacidad de deformación plástica en frío deficiente.

Leer más: Diferencia entre tubería de acero dulce y tubería de acero al carbono o Normas para tuberías de acero dulce

Eastern Steel Manufacturing Co., Ltd no solo mejora la producción de productos y los servicios de venta, sino que también brinda servicios adicionales de valor agregado. Siempre que lo necesite, podemos completar sus necesidades específicas juntos.

Eastern Steel Manufacturing Co., Ltd no solo mejora la producción de productos y los servicios de venta, sino que también brinda servicios adicionales de valor agregado. Siempre que lo necesite, podemos completar sus necesidades específicas juntos.