Los tubos de acero al carbono sin costura se fabrican a partir de lingotes de acero o piezas sólidas perforadas para formar tubos capilares y posteriormente se fabrican mediante laminación en caliente, laminación en frío o estirado en frío. En cuanto al calibre, <φ76 representa el 35% y <φ159-650 el 25%. En cuanto a las variedades, los tubos de uso general representan 1,9 millones de toneladas, lo que representa el 54%; los tubos para petróleo, 760.000 toneladas, el 5,7%; los tubos para apoyos hidráulicos y de precisión, 150.000 toneladas, el 4,3%; y los tubos de acero inoxidable, los tubos para cojinetes y los tubos para automóviles, 50.000 toneladas, el 1,4%.

Los tubos de acero al carbono sin costura se componen principalmente de hierro y carbono, con un contenido de carbono que suele oscilar entre el 0,02% y el 2,0%. Las tuberías de acero al carbono se clasifican en acero de bajo carbono, acero de medio carbono y acero de alto carbono según su contenido de carbono. El acero de bajo carbono (como el Q235) ofrece mayor plasticidad y soldabilidad, mientras que el acero de alto carbono ofrece mayor resistencia pero menor tenacidad.

El rendimiento de las tuberías de acero al carbono sin costura generalmente está estrechamente relacionado con su contenido de carbono. Un mayor contenido de carbono aumenta la dureza y la resistencia del acero, pero reduce su plasticidad y soldabilidad. Las tuberías de acero al carbono sin costura también presentan una resistencia a la corrosión relativamente baja y son propensas a la oxidación.

Las tuberías de acero inoxidable sin costura son resistentes a medios corrosivos débiles como el aire, el vapor y el agua, y a medios químicamente corrosivos como ácidos, álcalis y sales. También se conocen como tuberías de acero inoxidable resistentes a los ácidos.

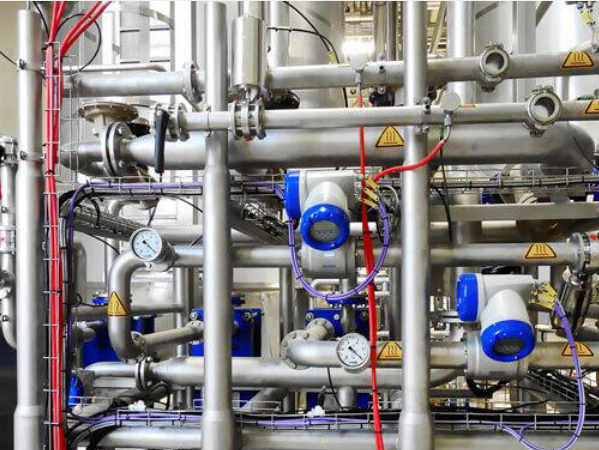

Las tuberías de acero inoxidable sin costura son aceros huecos, largos y redondos, ampliamente utilizados en las industrias petrolera, química, médica, alimentaria, ligera, de instrumentación mecánica y otras tuberías industriales y componentes estructurales mecánicos. Además, al igualar la resistencia a la flexión y a la torsión, el peso es menor, por lo que se utiliza ampliamente en la fabricación de piezas mecánicas y estructuras de ingeniería. También se utiliza comúnmente para producir diversas armas convencionales, cañones, proyectiles, etc.

Proceso de producción de tubos de acero inoxidable sin costura

a. Preparación del acero redondo; b. Calentamiento; c. Perforación por laminación en caliente; d. Cabezal de corte; e. Decapado; f. Rectificado; g. Lubricación; h. Laminado en frío; i. Desnatado; j. Tratamiento térmico de disolución; k. Enderezado; l. Corte de tubos; m. Decapado; n. Pruebas del producto.

Tubería de acero inoxidable sin costura vs. tubería de acero al carbono sin costura: Diferencias de rendimiento

1. Resistencia a la corrosión

Tubería de acero inoxidable sin costura:

La mayor ventaja del acero inoxidable reside en su excelente resistencia a la corrosión. La tubería de acero inoxidable mantiene una larga vida útil en ambientes ácidos, alcalinos, de niebla salina y húmedos, lo que la hace especialmente adecuada para aplicaciones con altos requisitos de corrosión, como la industria química, la ingeniería naval, el procesamiento de alimentos y la industria médica.

El acero inoxidable 316, en particular, presenta una excelente resistencia a la corrosión en ambientes con iones de cloruro y se utiliza comúnmente en entornos marinos.

Tubería de acero al carbono sin costura:

La tubería de acero al carbono sin costura presenta baja resistencia a la corrosión, especialmente en ambientes húmedos o con alta concentración de sustancias químicas, donde es propensa a la corrosión oxidativa y la oxidación.

Para prolongar su vida útil, la tubería de acero al carbono suele pintarse o galvanizarse, pero estos recubrimientos protectores tienden a degradarse con el tiempo, reduciendo su resistencia a la corrosión. Por lo tanto, la tubería de acero al carbono sin costura es más adecuada para su uso en ambientes secos y templados.

2. Resistencia y Dureza

Tuberías de Acero Inoxidable sin Costura:

Las tuberías de acero inoxidable sin costura generalmente presentan mayor resistencia que las tuberías de acero al carbono sin costura convencionales, especialmente el acero inoxidable austenítico. Su resistencia y resistencia a altas temperaturas permiten que las tuberías de acero inoxidable se utilicen en condiciones exigentes.

Por ejemplo, en entornos de alta temperatura, el acero inoxidable mantiene excelentes propiedades mecánicas y presenta una mejor resistencia al choque térmico.

Tuberías de Acero al Carbono sin Costura:

La resistencia y la dureza de las tuberías de acero al carbono están estrechamente relacionadas con su contenido de carbono. Las

tuberías de acero dulce presentan buena tenacidad y ductilidad, lo que las hace adecuadas para la mayoría de las aplicaciones estructurales; las

tuberías de acero con alto contenido de carbono, por otro lado, presentan mayor resistencia pero menor plasticidad.

En general, la resistencia de las tuberías de acero al carbono sin costura no es tan alta como la de las tuberías de acero inoxidable, pero su dureza suele ser suficiente para el uso general.

3. Resistencia a altas temperaturas

Tuberías de Acero Inoxidable sin Costura:

Las tuberías de acero inoxidable sin costura ofrecen un rendimiento excepcional en entornos de alta temperatura. Pueden soportar altas temperaturas de operación y, por lo general, son menos susceptibles a la deformación u oxidación.

Por ejemplo, el acero inoxidable 304 puede utilizarse continuamente por debajo de los 800 °C, mientras que el acero inoxidable 316 puede operar a temperaturas más altas, lo que lo hace adecuado para industrias con altas temperaturas, como la química, la petrolera y la aeroespacial.

Tuberías de acero al carbono sin costura:

Las tuberías de acero al carbono sin costura tienen una resistencia relativamente baja a altas temperaturas. Generalmente, son susceptibles a la oxidación en entornos de alta temperatura y su resistencia disminuye significativamente a altas temperaturas.

Para mantener la estabilidad estructural a altas temperaturas, las tuberías de acero al carbono requieren un tratamiento térmico especial y recubrimientos protectores.

4. Procesamiento y soldabilidad

Tuberías de acero inoxidable sin costura:

Las tuberías de acero inoxidable sin costura ofrecen una excelente soldabilidad, especialmente los aceros inoxidables austeníticos, que pueden soldarse con alta calidad mediante métodos como la soldadura TIG y MIG.

Aunque puede producirse corrosión intergranular en algunas zonas durante la soldadura, esta puede evitarse eficazmente con un tratamiento térmico adecuado y procedimientos de soldadura apropiados.

Tuberías de acero al carbono sin costura:

Las tuberías de acero al carbono sin costura ofrecen una excelente soldabilidad y casi todos los tipos de acero al carbono pueden soldarse mediante métodos de soldadura convencionales.

En comparación con las tuberías de acero inoxidable sin costura, las tuberías de acero al carbono son más fáciles de procesar y menos costosas, lo que las hace ampliamente utilizadas en diversas aplicaciones estructurales y de tuberías.

Tuberías de acero inoxidable sin costura vs. tuberías de acero al carbono sin costura: Costo y asequibilidad

Tuberías de acero inoxidable sin costura:

Debido al coste relativamente elevado de las materias primas y al complejo proceso de producción, el coste de las tuberías de acero inoxidable sin costura es relativamente alto.

Especialmente en aplicaciones que requieren alta resistencia a la corrosión y resistencia, el coste de las tuberías de acero inoxidable sin costura puede ser varias veces superior al de las tuberías de acero al carbono sin costura. Por lo tanto, las tuberías de acero inoxidable sin costura son principalmente adecuadas para aplicaciones que requieren un alto rendimiento.

Tuberías de acero al carbono sin costura:

Las tuberías de acero al carbono sin costura tienen un coste de producción menor y una adquisición de materia prima relativamente económica.

Es ideal para aplicaciones con presupuestos limitados y requisitos de resistencia a la corrosión y robustez relativamente bajos. Se utiliza ampliamente en tuberías de agua, oleoductos y gasoductos, entre otros campos.

Tubería de acero inoxidable sin costura vs. tubería de acero al carbono sin costura: Escenarios de aplicación

1. Aplicaciones de la tubería de acero inoxidable sin costura

Industria química: Debido a su excelente resistencia a la corrosión, la tubería de acero inoxidable se utiliza ampliamente en reactores químicos, tuberías de transmisión y otros equipos.

Industria alimentaria: La tubería de acero inoxidable sin costura se utiliza ampliamente en el procesamiento de alimentos, especialmente en entornos donde la higiene alimentaria es crucial. Gracias a su fácil limpieza y resistencia a la oxidación, la tubería de acero inoxidable es ideal para las líneas de producción de alimentos y bebidas.

Industria médica: La tubería de acero inoxidable sin costura se utiliza ampliamente en la fabricación de equipos y dispositivos médicos, como tubos intravenosos y catéteres.

Industria de la construcción: La tubería de acero inoxidable sin costura se utiliza en decoración arquitectónica y aplicaciones estructurales, especialmente en aplicaciones que deben soportar entornos corrosivos, como la ingeniería naval y la decoración de paredes exteriores.

2. Aplicaciones de la tubería de acero al carbono sin costura

Tratamiento de aguas: La tubería de acero al carbono sin costura se utiliza ampliamente en sistemas de suministro y drenaje de agua urbana, así como en sistemas de tuberías de plantas de tratamiento de agua.

Industria del petróleo y el gas: La tubería de acero al carbono es el material principal para la transmisión de petróleo y gas natural. Debido a su bajo costo, los tubos de acero al carbono sin costura se utilizan ampliamente en tuberías de transmisión de larga distancia, especialmente en entornos sin medios particularmente corrosivos.

Industria de la construcción: Los tubos de acero al carbono sin costura se utilizan a menudo para estructuras de soporte y de acero en la construcción de edificios, especialmente en aplicaciones con requisitos estructurales más bajos.

Industria automotriz: Los tubos de acero al carbono sin costura se utilizan en la fabricación de automóviles, como en sistemas de refrigeración y líneas de combustible.

¿Tuberías de acero inoxidable sin costura o de acero al carbono sin costura?

Tras analizar las diferencias de rendimiento y los escenarios de aplicación de los tubos de acero inoxidable sin costura y de acero al carbono sin costura, concluimos que si su proyecto implica alta corrosión, altas temperaturas o entornos especiales, los tubos de acero inoxidable sin costura son, sin duda, la mejor opción. A pesar de su mayor costo, su excelente resistencia a la corrosión y resistencia los hacen ideales para aplicaciones de alta gama como la ingeniería química, petrolera y naval.

Para aplicaciones estructurales generales, especialmente donde el costo es limitado, los tubos de acero al carbono sin costura son una opción económica y práctica. Los tubos de acero al carbono no solo ofrecen ventajas en la construcción y la soldadura, sino que también ofrecen un rendimiento adecuado en muchos proyectos cotidianos, especialmente en los sectores de las tuberías de agua y el transporte de petróleo.

Eastern Steel Manufacturing Co., Ltd no solo mejora la producción de productos y los servicios de venta, sino que también brinda servicios adicionales de valor agregado. Siempre que lo necesite, podemos completar sus necesidades específicas juntos.

Eastern Steel Manufacturing Co., Ltd no solo mejora la producción de productos y los servicios de venta, sino que también brinda servicios adicionales de valor agregado. Siempre que lo necesite, podemos completar sus necesidades específicas juntos.