DIN EN 10220

DIN EN 10220, también conocida como tubos acero sin costura y tubos soldados - Dimensiones y masas por unidad de longitud

Al adaptar la norma europea ENV 10220 a la norma EN 10220, el ECISS/TC 29 consideró necesario evitar cualquier conflicto con la norma ISO 4200:1991 y minimizar las desviaciones derivadas del comercio internacional de tubos y productos tubulares de acero.

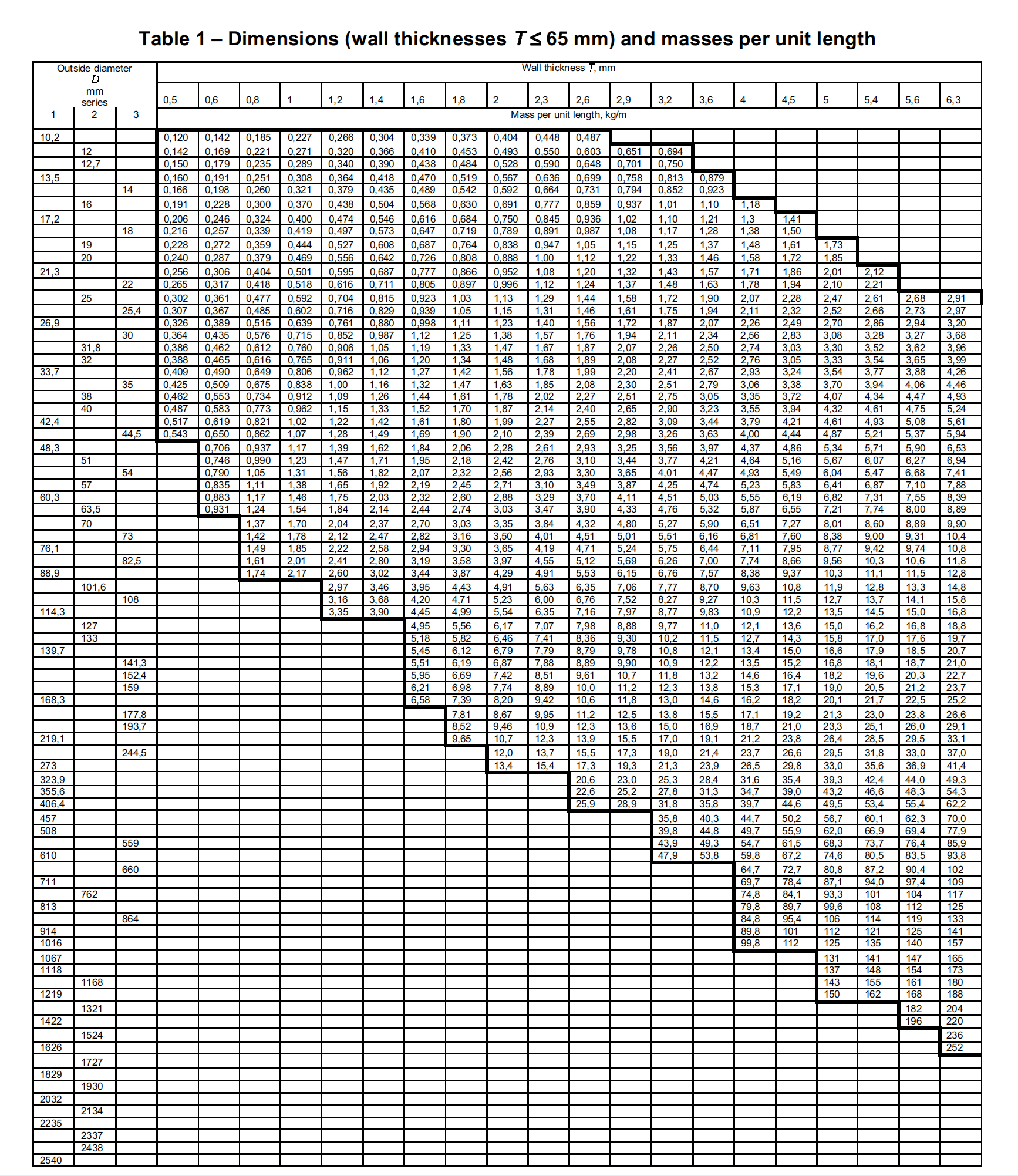

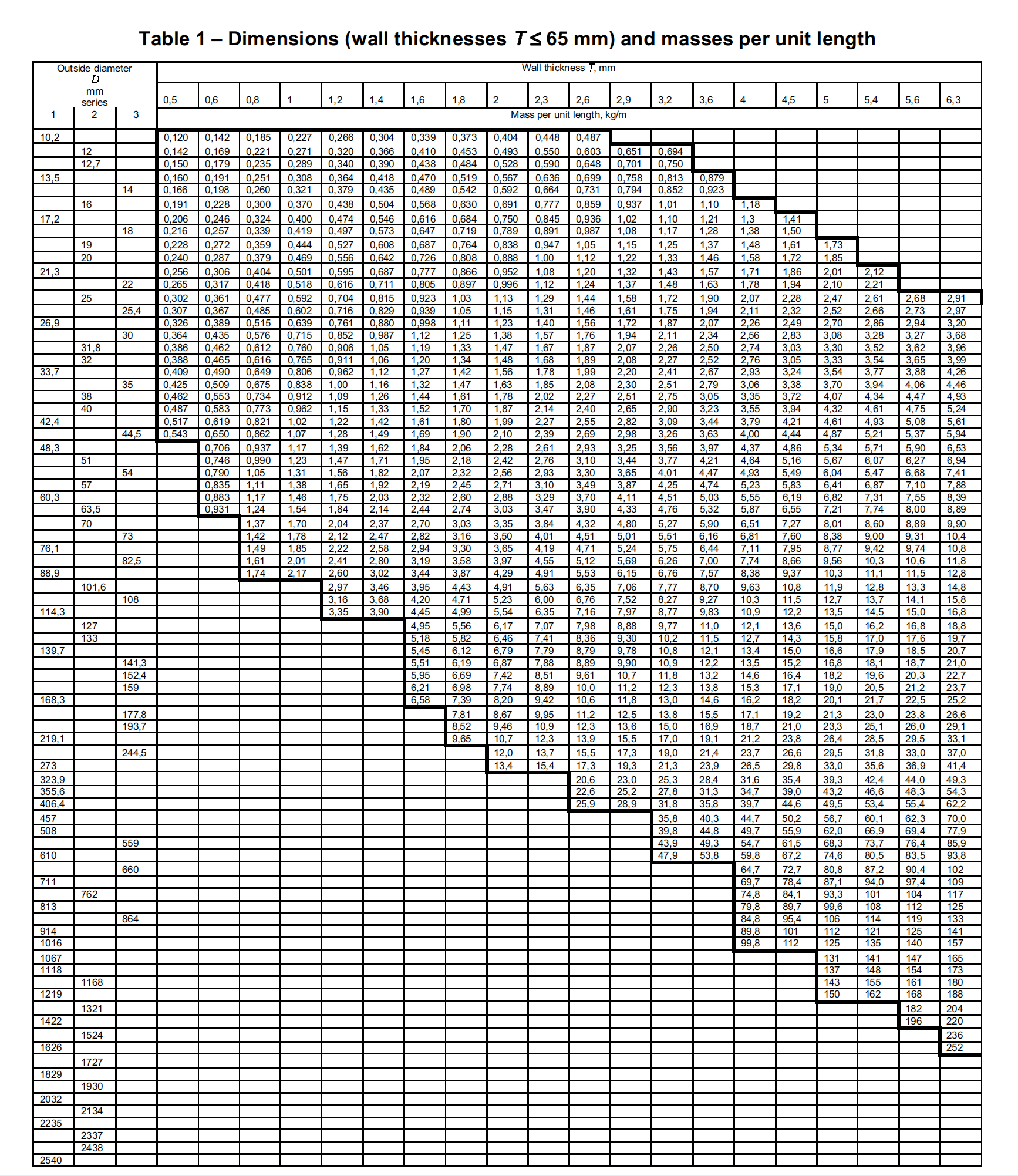

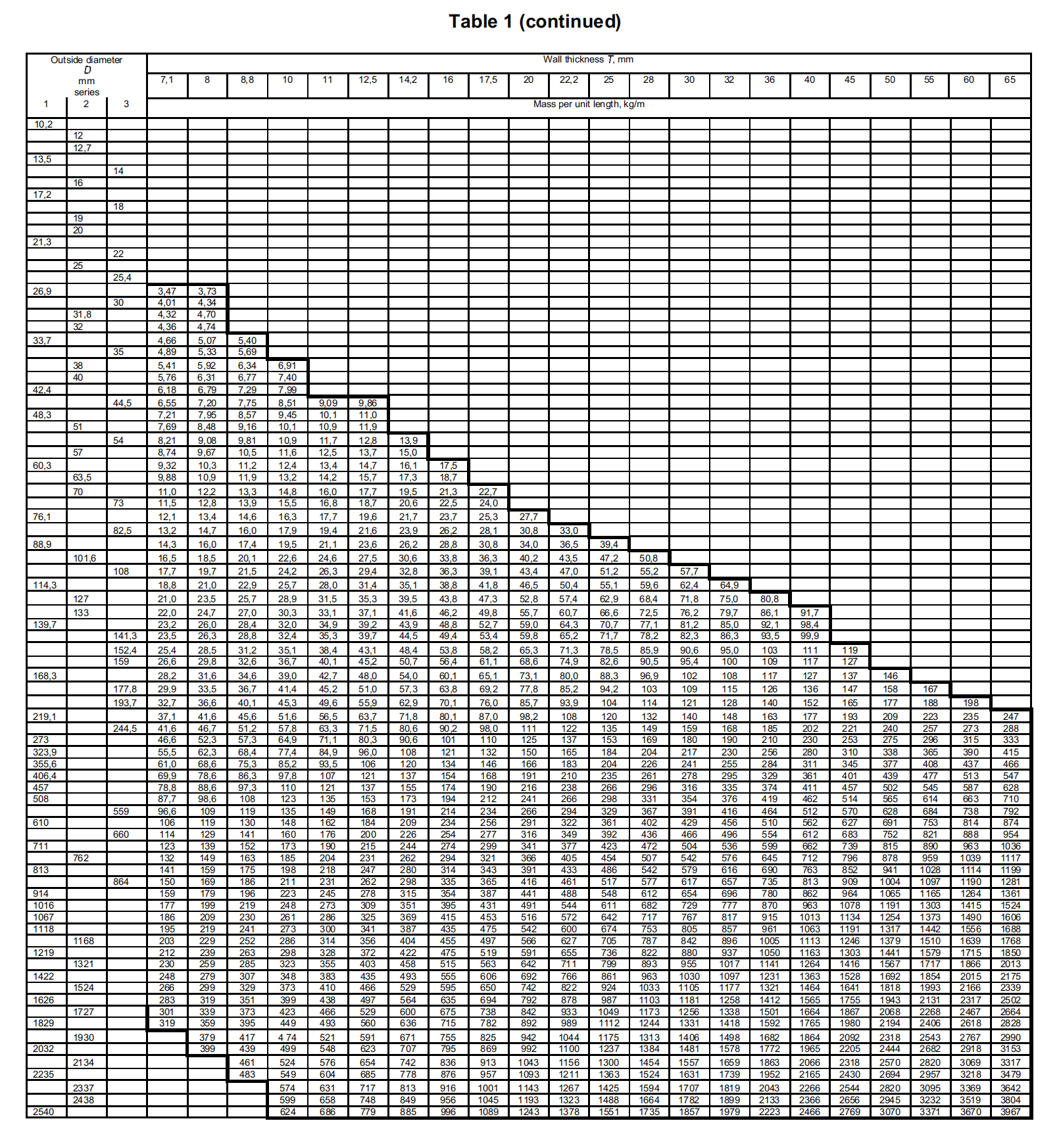

La Tabla 1 de la norma ENV 10220 es la misma que la Tabla 2 de la norma ISO 4200:1991 y, por lo tanto, se mantiene sin cambios para la norma EN 10220.

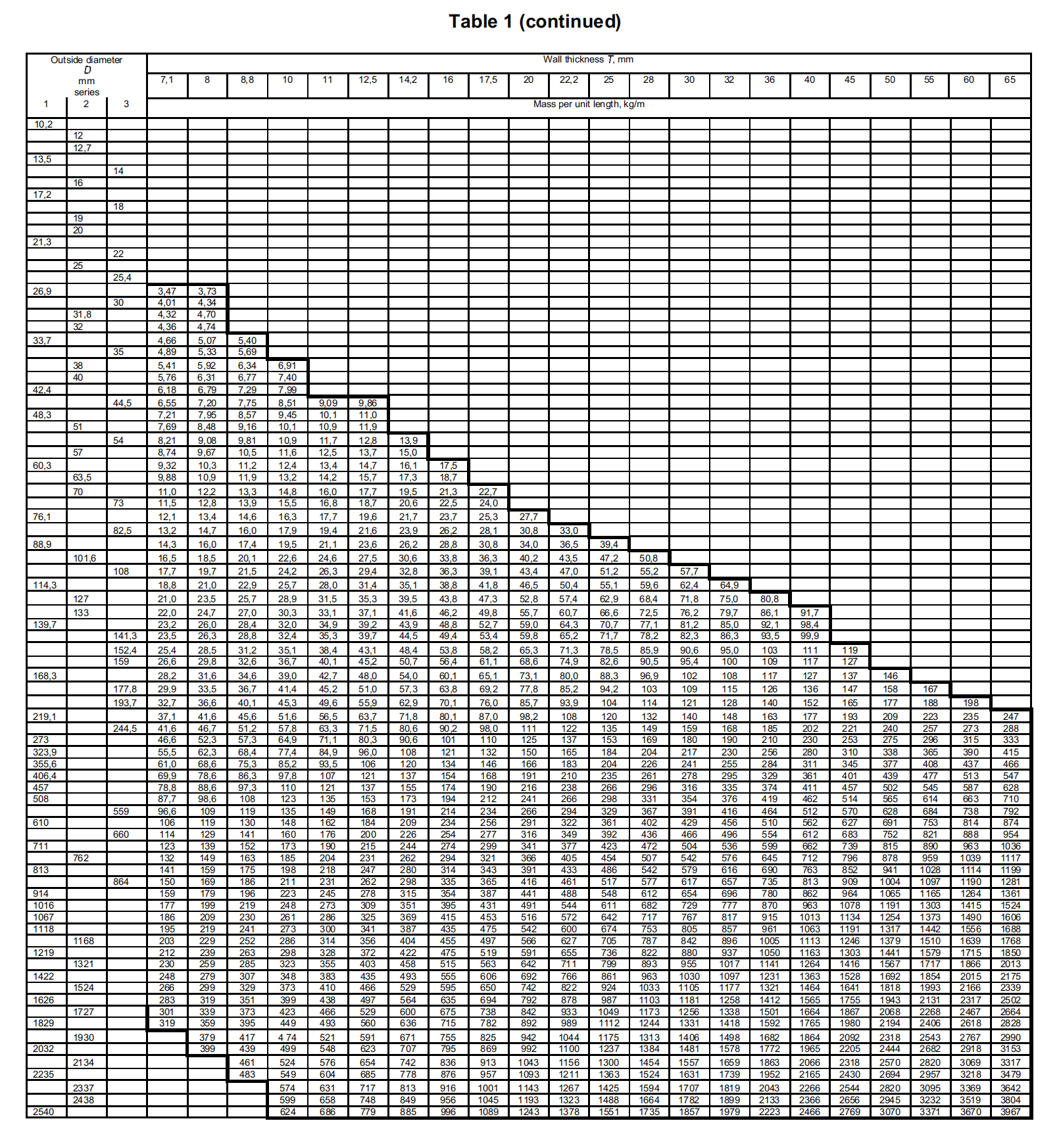

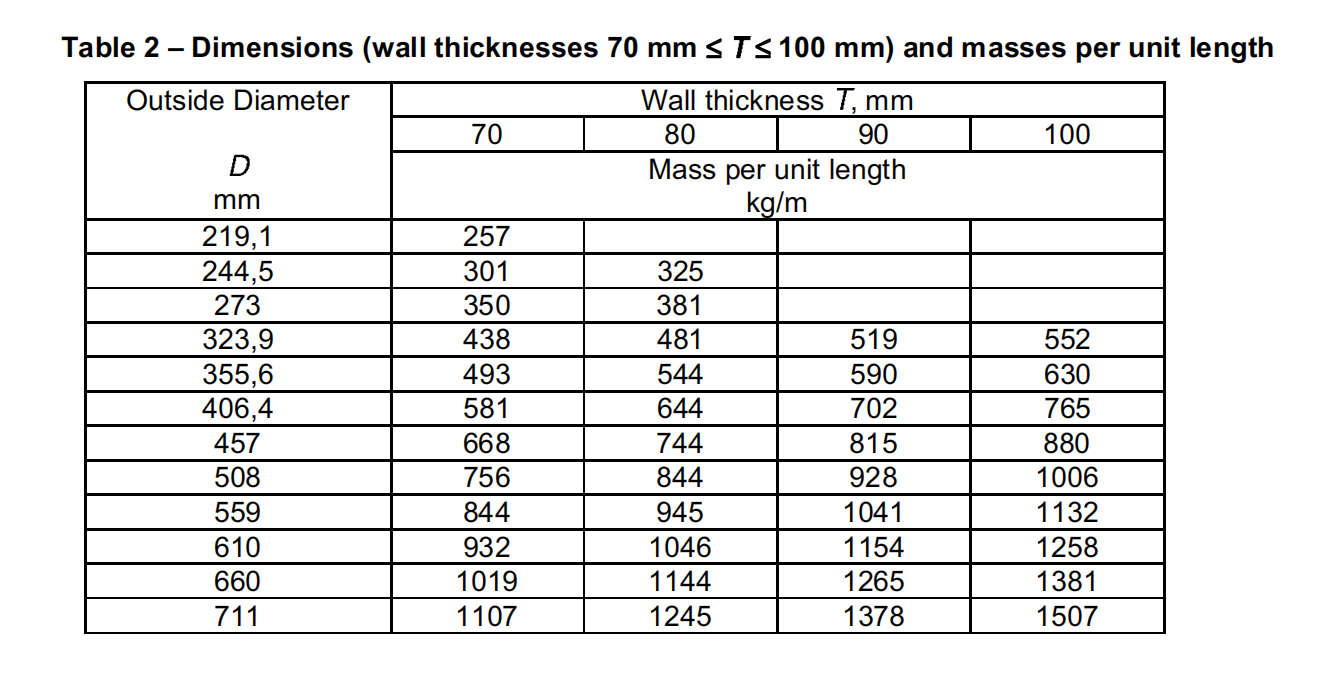

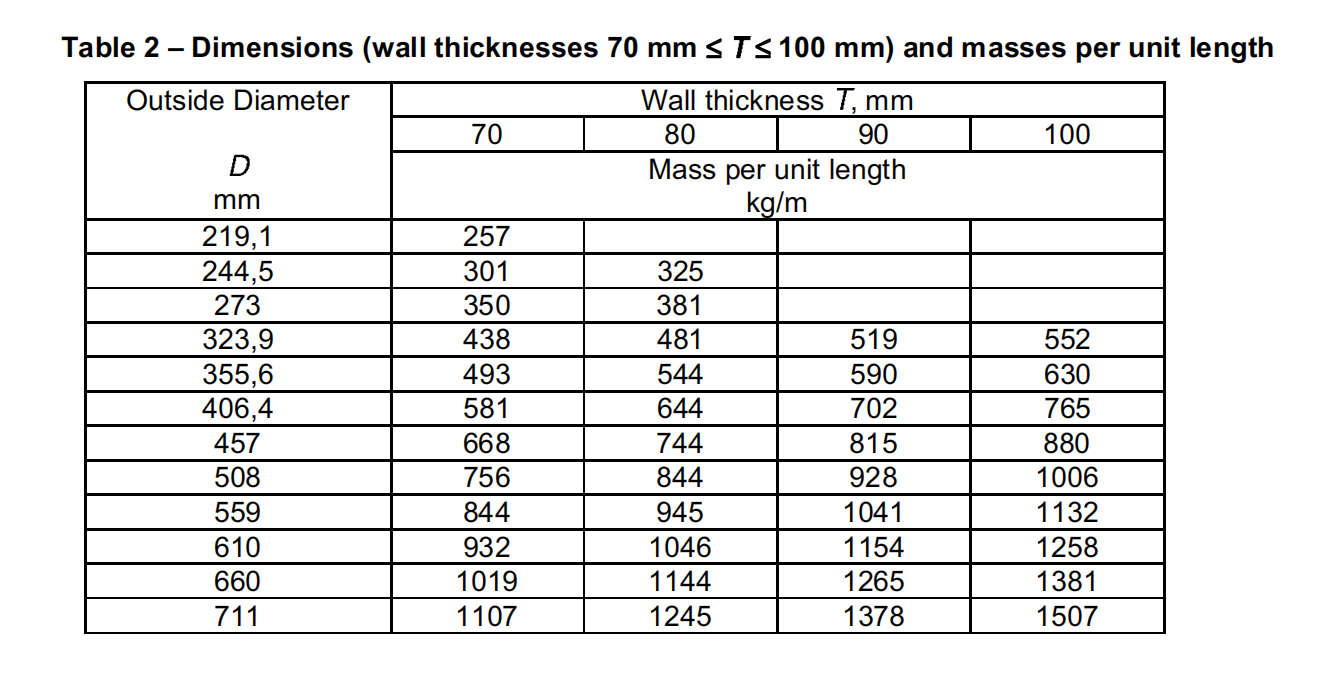

La Tabla 2 de la norma EN 10220 contiene las dimensiones de los tubos de pared gruesa no contemplados en la norma ISO 4200:1991.

Las normas EN 10220 y EN 1127 regulan las dimensiones y tolerancias de los tubos europeos, los aceros al carbono/aleados y los aceros inoxidables, respectivamente. Si bien las normas EN 10220 y 1127 se utilizan en Europa, las normas ASME B36.10 y ASME B36.19 cubren las dimensiones y tolerancias de las tuberías estándar estadounidenses.

Todas las partes de la serie de normas europeas EN 10305 sobre tubos de acero para aplicaciones de precisión contienen tablas con las dimensiones preferidas específicas para cada parte de la serie, así como para los productos y áreas de aplicación que allí se especifican. Por lo tanto, las dimensiones preferidas para tubos de acero para aplicaciones de precisión de la Tabla 3 de la norma ENV 10220 ya no son necesarias y no se incluyen en esta norma.

Este documento sustituye a la norma ENV 10220:1993.

De acuerdo con el Reglamento Interno de CEN/CENELEC, los organismos nacionales de normalización de los siguientes países están obligados a implementar esta norma europea: Alemania, Austria, Bélgica, Dinamarca, España, Finlandia, Francia, Grecia, Irlanda, Islandia, Italia, Luxemburgo, Malta, Noruega, Países Bajos, Portugal, Reino Unido, República Checa, Suecia y Suiza.

Aspectos clave de la norma EN 10220

La norma EN 10220 tiene como objetivo estandarizar las especificaciones dimensionales de las tuberías de acero en toda Europa, promover la interoperabilidad y garantizar que las tuberías de acero cumplan con los requisitos de calidad y rendimiento de diversas aplicaciones.

1. Alcance

Abarca las tuberías de acero soldadas y sin costura para aplicaciones a presión (excepto la soldadura por arco sumergido), los ensayos de partículas magnéticas de circunferencia completa para la detección de defectos longitudinales y los ensayos ultrasónicos para la detección de defectos laminares.

2. Diámetro exterior y espesor de pared

La norma proporciona tablas detalladas que especifican las variaciones admisibles en el diámetro exterior y el espesor de pared de las tuberías de acero, lo cual es fundamental para garantizar que las tuberías sean adecuadas para la presión y los requisitos estructurales previstos.

3. Tolerancia de longitud

La norma EN 10220 también especifica las tolerancias en las longitudes de las tuberías, incluyendo las longitudes estándar y las variaciones admisibles. Esto es crucial para garantizar que las tuberías se puedan instalar correctamente en los sistemas de tuberías o estructurales diseñados sin modificaciones excesivas.

4. Tolerancia de forma

Incluye tolerancias de rectitud y redondez, lo que garantiza que las tuberías se puedan instalar y soldar con precisión en diversas configuraciones y aplicaciones. La norma EN 10220 proporciona un conjunto completo de especificaciones y tolerancias dimensionales que ayudan a garantizar la calidad y la compatibilidad de las tuberías de acero utilizadas en los sectores de la construcción, la ingeniería y la fabricación en toda Europa. Esta estandarización contribuye a mejorar la eficiencia del diseño, la especificación y la adquisición de tuberías de acero, mejorando así la seguridad, la fiabilidad y el rendimiento general de los sistemas de tuberías y los proyectos estructurales.

Ámbito de aplicación

1. Ámbito de aplicación

Esta Norma Europea especifica, para tubos de acero circulares soldados y sin costura para usos generales, como aplicaciones mecánicas, de presión y estructurales, que:

- Dimensiones preferidas para el diámetro exterior y el espesor de pared en milímetros; y

- Masa por unidad de longitud en kilogramos por metro de tubo liso.

Los comités técnicos de ECISS y CEN seleccionarán estas dimensiones preferidas para sus normas de producto o funcionales, según corresponda.

Los diámetros exteriores se agrupan en tres series que reflejan la disponibilidad de accesorios para sistemas de tuberías. Esta clasificación de los diámetros exteriores en diferentes series y espesores de pared preferidos indica la gama de tubos de acero que se fabrican habitualmente.

NOTA: La información sobre las dimensiones de las tuberías de acero para aplicaciones especiales se puede encontrar en otras normas europeas, como la norma prEN 10255, la serie EN 10305, las normas EN ISO 11960 y EN ISO 11961. La información sobre las dimensiones de las tuberías de acero inoxidable se encuentra en la norma EN ISO 1127.

2. Reglamento

Tuberías de acero redondas, sin costura y soldadas, para usos generales (p. ej., aplicaciones mecánicas, de presión y estructurales), como se indica a continuación:

Dimensiones preferidas en mm para el diámetro exterior y el espesor de pared, y masa por unidad de longitud en kg/m para tuberías de extremo liso.

Los comités técnicos de ECISS y CEN seleccionarán estas dimensiones preferidas para sus normas de producto o funcionales, según corresponda.

Los diámetros exteriores se dividen en tres series que reflejan la disponibilidad de accesorios para sistemas de tuberías (véase el capítulo 4). Esta clasificación de los diámetros exteriores en diferentes series y espesores de pared preferidos indica la gama de tuberías de acero que se fabrican habitualmente.

3. Notas

La información sobre las dimensiones de las tuberías de acero para aplicaciones especiales se puede encontrar en otras normas europeas, como la norma prEN 10255, la serie EN 10305, las normas EN ISO 11960 y EN ISO 11961. La información sobre las dimensiones de las tuberías de acero inoxidable se encuentra en la norma EN ISO 1127.

Términos y definiciones

A este respecto, se aplican los términos y definiciones de la norma prEN 10266.

Clasificación del diámetro exterior

Los diámetros exteriores que se indican en las Tablas 1 y 2 se dividen en tres series, que pueden describirse de la siguiente manera:

Serie 1: cuyo diámetro exterior está normalizado para todos los accesorios necesarios para la construcción del sistema de tuberías;

Serie 2: diámetro exterior no normalizado para todos los accesorios;

Serie 3: Existen pocos accesorios normalizados para los diámetros exteriores.

NOTA 1: Para tuberías destinadas a ser utilizadas como componente de un sistema de tuberías, se recomienda seleccionar un diámetro exterior de la Serie 1 de la Tabla 1. Es posible que las tuberías con diámetros exteriores de las series 2 y 3 no estén disponibles o no se consigan fácilmente.

NOTA 2: Los accesorios para tuberías de pared gruesa dimensionados en la Tabla 2 podrían no estar disponibles, independientemente de la serie a la que se asigne el diámetro exterior correspondiente de la Tabla 1.

Método de cálculo de la masa por unidad de longitud

Las masas por unidad de longitud indicadas en las Tablas 1 y 2 se han calculado con al menos cinco cifras significativas a partir del diámetro exterior D y el espesor de pared T, utilizando la fórmula que se indica a continuación. Los valores inferiores a 100 se redondean a tres cifras significativas y los valores superiores se redondean al número entero más cercano.

M = (D-T)T x 0,02466151) kg/m

Donde

M es la masa por unidad de longitud en kg/m,

D es el diámetro exterior especificado,

T es el espesor de pared especificado en milímetros.

Los valores calculados también pueden aplicarse a tubos con diferentes valores de densidad, pero deben multiplicarse por un factor:

-- 1,015 para acero inoxidable austenítico2)

-- 0,985 para acero inoxidable ferrítico y martensítico3)

NOTA: La norma EN 10088-1 proporciona diferentes valores de densidad para diversos grupos de calidades de acero inoxidable que pueden utilizarse para fines de cálculo.

Dimensiones y masa por unidad de longitud

La Tabla 1 muestra las dimensiones, incluido el diámetro exterior D, de las tres series descritas en el Capítulo 4, el espesor de pared correspondiente Ts 65 mm y la masa por unidad de longitud calculada del tubo de extremo liso.

Table 2 gives the dimensions consisting of the outer diameter D and the associated wall thickness T from 70 mm to 100 mml and the calculated mass per unit length of plain-end tubes.

Resumen

EN 10220 es la norma europea para dimensiones y tolerancias de tubos de acero soldados y sin costura. Su uso es amplio, principalmente en las industrias del petróleo y el gas, química, construcción y agua. Al abarcar el diámetro exterior (DE) y el espesor de pared (PE) de los tubos de acero, proporciona directrices claras y especificaciones uniformes para el diseño y la fabricación de ingeniería, garantizando la consistencia y la intercambiabilidad entre tubos de diferentes fabricantes.

Leer más: EN10220 vs EN10210 o Tabla de pesos de tuberías según norma EN 10220

Eastern Steel Manufacturing Co., Ltd no solo mejora la producción de productos y los servicios de venta, sino que también brinda servicios adicionales de valor agregado. Siempre que lo necesite, podemos completar sus necesidades específicas juntos.

Eastern Steel Manufacturing Co., Ltd no solo mejora la producción de productos y los servicios de venta, sino que también brinda servicios adicionales de valor agregado. Siempre que lo necesite, podemos completar sus necesidades específicas juntos.