¿Qué es una tubería sin costura?

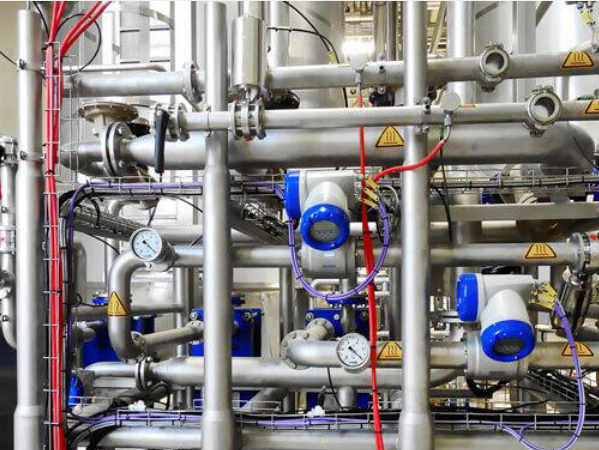

La tubería sin costura es una variante de tubería de acero fabricada sin uniones soldadas, de ahí su nombre. La tubería sin costura no tiene costuras, lo que reduce el riesgo de fractura bajo alta presión y tensión. A diferencia de la tubería soldada, la tubería sin costura tiene una superficie más lisa y un diámetro más uniforme.

Estas características le confieren una durabilidad y resistencia a la corrosión excepcionales. Todas estas cualidades excepcionales la convierten en la opción ideal para la industria del petróleo y el gas, así como para la construcción.

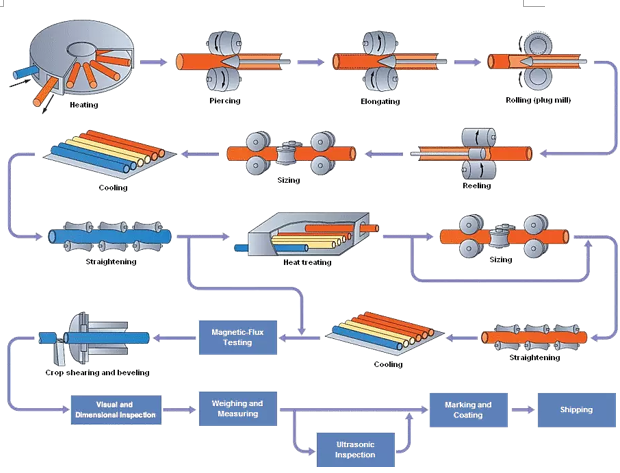

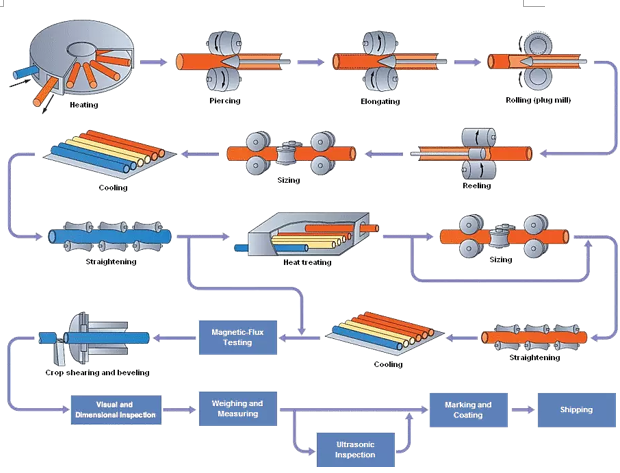

Procesos clave de tubos de acero sin costura

La producción de tubos sin costura comienza con una palanquilla redonda sólida. Tras calentarse a alta temperatura, la palanquilla se lamina en una carcasa hueca mediante un laminador de perforación. Posteriormente, se lamina mediante múltiples pasadas, dimensionado y tratamiento térmico para obtener tubos sin costura que cumplen con los requisitos dimensionales y de rendimiento.

Los Procesos Clave Incluyen:

1. Perforación

El laminado de la palanquilla caliente en una carcasa hueca es el proceso clave que distingue los tubos sin costura de los

tubos con costura.

2. Laminado y alargamiento

La carcasa se extiende mediante un laminador continuo o un laminador de tubos para controlar el diámetro exterior y el espesor de la pared.

3. Dimensionado/reducción

Ajusta aún más el diámetro del tubo para garantizar dimensiones geométricas precisas.

4. Tratamiento térmico

Mejora la microestructura y las propiedades, mejorando la tenacidad, la ductilidad y la resistencia a la corrosión.

Proceso detallado de producción de tubos sin costura

1. Selección de la materia prima

Los tubos sin costura son una opción duradera para una amplia gama de aplicaciones. Sin embargo, para maximizar su versatilidad, deben ofrecer una variedad de materiales de procesamiento. La selección de la materia prima es clave para lograr las propiedades deseadas, como la resistencia a la tracción, el límite elástico y la dureza.

Los siguientes son los materiales más utilizados para la fabricación de tubos sin costura:

Acero al carbono

Usado comúnmente para tuberías de uso general, ofrece buena resistencia y soldabilidad. Es adecuado para aplicaciones de baja presión, como sistemas de agua, gas y criogénicos.

Acero aleado

Compuesto por elementos de aleación como cromo, níquel y molibdeno. Esta composición proporciona mayor resistencia, tenacidad, resistencia al calor y resistencia a la corrosión.

Acero inoxidable

Garantiza una excelente resistencia a la corrosión y tenacidad. Se utiliza comúnmente en entornos corrosivos, como el procesamiento marino y químico.

2. Calentamiento

La palanquilla de acero se calienta a una temperatura alta de 1150 °C a 1250 °C para alcanzar un estado dúctil. El control de la temperatura es crucial; una temperatura demasiado baja puede dificultar la perforación, mientras que una temperatura demasiado alta puede causar granos gruesos.

3. Extrusión

Herramientas rotativas industriales penetran la palanquilla caliente, formando una carcasa hueca de tubo. El proceso de trefilado pasa la carcasa por una serie de rodillos pesados, hasta obtener la forma y las dimensiones iniciales deseadas para el tubo.

4. Expansión

Durante el proceso de expansión, los operarios presionan continuamente un mandril en el tubo. Este paso es crucial para garantizar un diámetro interior liso y un espesor de pared uniforme. El fresado con mandril implica el laminado y trefilado continuos hasta alcanzar las dimensiones deseadas.

5. Enfriamiento

La palanquilla del tubo laminado se enfría en un entorno controlado para evitar el agrietamiento causado por la tensión térmica. A menudo se utiliza refrigeración por aire o refrigeración controlada para mantener una microestructura uniforme.

6. Enderezado

Incluso después del enfriamiento, el tubo se deformará y doblará. Por lo tanto, la tubería aún necesita pasar por rodillos o enderezadoras para aplicar una presión controlada y alinearla. Esto garantiza la precisión geométrica y la usabilidad de la tubería sin costura final.

7. Posprocesamiento

El posprocesamiento puede incluir pulido superficial, roscado o tratamiento térmico para mejorar el rendimiento de la tubería. Los trabajadores también pueden añadir recubrimientos superficiales para prevenir el desgaste y la corrosión.

8. Control de calidad

El departamento de control de calidad inspecciona las tuberías para verificar su precisión dimensional, resistencia y defectos superficiales. Los mecanismos de inspección de seguridad, que incluyen pruebas de rayos X y ultrasonidos, garantizan que las tuberías estén libres de defectos. Las tuberías se someten a una inspección final antes del envío.

Producción artesanal de tuberías de acero sin costura

Generalmente, los procesos de producción de tuberías de acero sin costura se dividen en laminado en frío y laminado en caliente.

Principales procesos de producción (principales procesos de inspección) para tubos de acero sin costura laminados en caliente:

Preparación e inspección de tubos → Calentamiento → Perforación → Laminado → Recalentamiento de tubos en bruto → Dimensionado (reducción) → Tratamiento térmico → Enderezamiento de tubos terminados → Acabado → Inspección (no destructiva, física y química, inspección de banco) → Almacenamiento

Los tubos de acero sin costura laminados en caliente se entregan generalmente laminados en caliente después del tratamiento térmico. Tras una rigurosa selección manual, se someten a una inspección de calidad. A continuación, se lubrica la superficie y se somete a múltiples pruebas de estirado en frío. Tras el laminado en caliente, se realiza una prueba de perforación. Si la perforación es demasiado grande, los tubos se enderezan. Tras el enderezamiento, se transportan mediante una cinta transportadora a un detector de defectos para su análisis. Finalmente, se etiquetan, se clasifican según las especificaciones y se almacenan.

El principal proceso de producción de tubos de acero sin costura laminados en frío (trefilados) es el siguiente:

Preparación de la pieza bruta → Decapado y lubricación → Laminado en frío (trefilado) → Tratamiento térmico → Enderezado → Acabado → Inspección

El proceso de producción de tubos de acero sin costura laminados en frío suele ser más complejo que el de los laminados en caliente. Si no se observan grietas de reacción en la superficie durante la prueba de dimensionamiento, el tubo redondo se corta con una máquina cortadora en piezas brutas de aproximadamente un metro de longitud. A continuación, se realiza un recocido, seguido de un decapado con ácido. Durante el decapado, preste atención a la posible formación de ampollas en la superficie. Si se observan ampollas significativas, la calidad del tubo no cumple con los estándares de reacción.

Aparentemente, los tubos de acero sin costura laminados en frío son más cortos que los laminados en caliente. El espesor de pared de los tubos de acero sin costura laminados en frío suele ser menor que el de los laminados en caliente. Sin embargo, la superficie de los tubos de acero sin costura laminados en frío parece mucho más brillante que la de los tubos de acero sin costura de paredes gruesas, con menos rugosidad y menos rebabas en el diámetro.

Tubos de acero sin costura laminados en caliente vs. Tubos de acero sin costura laminados en frío

|

Propiedades

|

Tuberías sin costura laminadas en caliente

|

Tuberías sin costura laminadas en frío

|

|

Temperatura de fabricación

|

Producido a altas temperaturas (>1000 °C)

|

Producido a temperatura ambiente o ligeramente superior

|

|

Acabado superficial

|

Áspero, puede presentar incrustaciones

|

Superficie lisa y limpia, mínima oxidación

|

|

Resistencia

|

Menor resistencia a la tracción y dureza

|

Mayor resistencia a la tracción, dimensiones más precisas

|

|

Costo

|

Más económico

|

Más costoso debido al procesamiento adicional

|

|

Aplicaciones

|

Usos de alta resistencia y baja precisión

|

Ingeniería de precisión, automoción, industria aeroespacial, recipientes a presión

|

Resumen

En resumen, la producción de tubos de acero sin costura es un proceso altamente sofisticado y complejo, que requiere la coordinación de múltiples pasos y medidas de control de calidad. Mediante un estricto control de la calidad de la materia prima, la optimización de los procesos de perforación y laminación, la selección racional de los métodos de tratamiento térmico y los procesos de acabado, y la implementación de rigurosas medidas de inspección y control, podemos producir tubos de acero sin costura de alta calidad que satisfacen las necesidades de varios sectores industriales.

Eastern Steel Manufacturing Co., Ltd no solo mejora la producción de productos y los servicios de venta, sino que también brinda servicios adicionales de valor agregado. Siempre que lo necesite, podemos completar sus necesidades específicas juntos.

Eastern Steel Manufacturing Co., Ltd no solo mejora la producción de productos y los servicios de venta, sino que también brinda servicios adicionales de valor agregado. Siempre que lo necesite, podemos completar sus necesidades específicas juntos.