El acabado en caliente es un método de procesamiento que provoca la deformación plástica y la recristalización simultánea de los materiales metálicos en condiciones superiores a la temperatura de recristalización. El acabado en caliente suele incluir fundición, forjado, soldadura, tratamiento térmico y otros procesos. El acabado en caliente puede modificar la estructura de las piezas metálicas durante su conformación o modificar el estado inicial de las piezas conformadas para mejorar sus propiedades mecánicas.

Principales procesos del acabado en caliente

1. Fundición

La fundición es un proceso que forma un producto con una forma específica vertiendo metal fundido en un molde y esperando a que se enfríe y solidifique. Este método se utiliza ampliamente para fabricar diversas piezas metálicas, especialmente aquellas con formas y estructuras internas complejas. Los pasos clave del proceso de fundición incluyen el diseño del molde, la fusión del metal, el vertido, el enfriamiento y el desmoldeo. La ventaja de la fundición es que permite fabricar piezas con formas complejas y un alto aprovechamiento del material. Sin embargo, también presenta algunas limitaciones, como la aparición de defectos como poros e inclusiones en el interior del producto, que afectan a sus propiedades mecánicas.

2. Forja

La forja es un proceso que aplica presión al metal a alta temperatura para provocar su deformación plástica y obtener la forma y el tamaño deseados. Este método se utiliza principalmente para fabricar piezas importantes que soportan grandes cargas y exigen alta resistencia, como cigüeñales de automóviles, bielas, etc. La forja puede mejorar la densidad y las propiedades mecánicas de los metales, así como reducir o eliminar defectos internos. Sin embargo, el proceso de forja consume mucha energía y requiere una gran inversión en equipos.

3. Soldadura

La soldadura es un proceso que funde dos o más partes de una unión metálica y luego las enfría y solidifica formando un todo. Este método se utiliza ampliamente en la fabricación y reparación de diversas estructuras metálicas, como puentes, edificios, barcos y automóviles. La principal ventaja de la soldadura es que permite unir diferentes tipos de materiales metálicos para formar una estructura integral. Sin embargo, pueden aparecer defectos como grietas, inclusiones de escoria y poros durante el proceso de soldadura, por lo que se requiere un control estricto de los parámetros del proceso y de las habilidades de operación.

Tubos de acero sin costura terminados en caliente

Los tubos sin costura terminados en caliente (HFS), a diferencia de los tubos sin costura estirados en frío (CDS), se fabrican calentando un tocho o barra sólida y luego punzándolo o perforándolo para crear un hueco. Este hueco se pasa posteriormente por uno o varios soportes, con o sin herramienta interna, para obtener las dimensiones finales del tubo o barra.

El proceso HFS permite fabricar tubos de gran diámetro y espesor, de diversos grados, en grandes volúmenes. Gracias a los avances tecnológicos, los tubos HFS ofrecen ahora una tolerancia dimensional estrecha y un buen acabado superficial.

Los tubos HFS son una alternativa rentable al estirado en frío, con un rango de tolerancia más amplio. Los tubos mecánicos sin costura terminados en caliente se fabrican según las dimensiones de diámetro exterior y pared.

Ventajas del acabado sin costuras con acabado en caliente (HFS)

1. Tubos de pared gruesa rentables.

2. Fácil maquinabilidad.

3. Excelentes para la mayoría de las técnicas de procesamiento.

4. Amplia gama de tamaños disponibles.

Diferencias entre el acabado en frío y el acabado en caliente de tubos sin costura

1. Temperatura de procesamiento

El acabado en caliente se realiza a una temperatura superior a la temperatura de recristalización; por ejemplo, en la producción de tubos laminados en caliente, la pieza bruta del tubo debe calentarse a una temperatura más alta. El acabado en frío se realiza a una temperatura inferior a la temperatura de recristalización, como en el trefilado y el laminado en frío.

2. Efecto del procesamiento

El acabado en caliente puede mejorar la estructura del metal fundido, refinar el grano, eliminar defectos internos, mejorar la plasticidad del metal y producir tubos sin costura de mayor tamaño y calidad superficial relativamente promedio. El acabado en frío puede mejorar significativamente la precisión dimensional y el acabado superficial de los tubos de acero, así como las propiedades mecánicas de los materiales, como el aumento de la resistencia y la dureza, pero provocará endurecimiento por deformación de los metales y reducirá la plasticidad.

3. Ámbito de aplicación

El acabado en caliente es adecuado para la producción de tubos sin costura de gran diámetro con bajos requisitos de precisión dimensional; el acabado en frío se utiliza a menudo para fabricar tubos sin costura de alta precisión y pequeño diámetro, para satisfacer las necesidades de industrias como la fabricación de maquinaria e instrumentos de precisión.

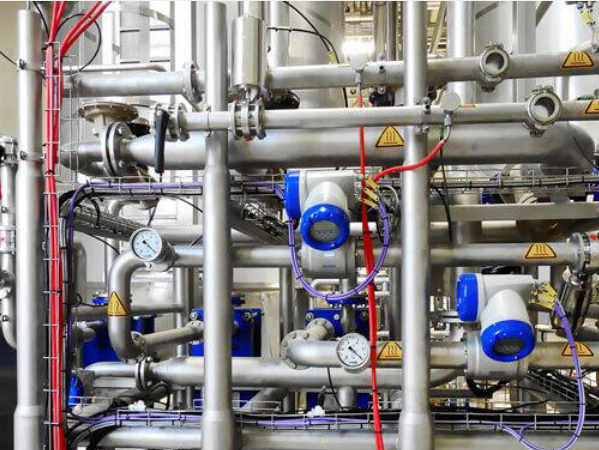

Aplicaciones de tubos y tuberías con acabado en caliente

Los tubos HFS están fabricados con acero 1020/1026 y cumplen con las normas ASTM A519 y A106. Disponemos de servicio de corte a medida. Los tubos HFS son ideales para aplicaciones de alta presión y servicio pesado que requieren resistencia. Se utilizan en una amplia gama de aplicaciones, como cilindros hidráulicos, equipos de perforación, bujes, espaciadores, ejes, rodillos y carcasas.

Read more: Proceso de tratamiento térmico de tubos de acero: Recocido or Proceso de tratamiento térmico de tubos de acero: Temple

Eastern Steel Manufacturing Co., Ltd no solo mejora la producción de productos y los servicios de venta, sino que también brinda servicios adicionales de valor agregado. Siempre que lo necesite, podemos completar sus necesidades específicas juntos.

Eastern Steel Manufacturing Co., Ltd no solo mejora la producción de productos y los servicios de venta, sino que también brinda servicios adicionales de valor agregado. Siempre que lo necesite, podemos completar sus necesidades específicas juntos.