What is the use of hydraulic tube?

The hydraulic tube is an essential component of various systems that are utilized within many industries. This article aims to provide a comprehensive overview of the uses of hydraulic tubes, their construction, safety considerations and applications in terms of different industries.

What is a Hydraulic Tube?

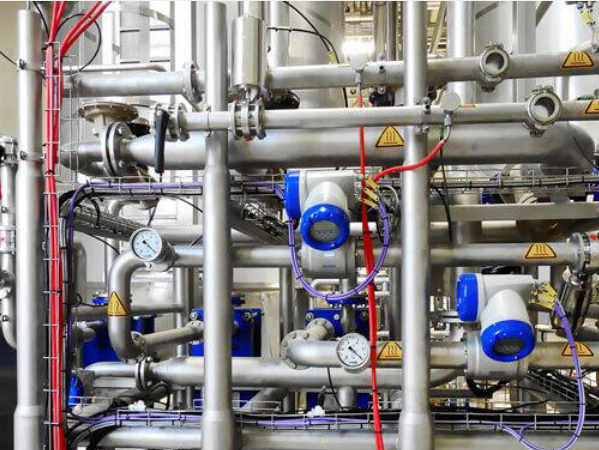

A hydraulic tube is a type of metal tube that is used in a variety of different industries. It is manufactured from materials such as steel, aluminum, brass, stainless steel and copper. The tube has an internal bore through which fluid is carried, and it has a connection point at one end to connect with other components such as valves, pumps and filters. A great benefit of using a hydraulic tube is its ability to keep a pressurized liquid or gas in the system without allowing any escapes or leaks.

The Different Uses of Hydraulic Tubes:

Hydraulic tubes are used in a variety of industrial and commercial applications. In the automotive industry, for example, these tubes are commonly used for fuel lines and power steering systems. Within mechanical engineering, this component is frequently used in pneumatic, hydraulic and lubrication systems. Additionally, some medical sectors use these tubes in medical instruments and devices such as laparoscopic tools.

Hydraulic Tube Construction:

The construction of hydraulic tubes is of utmost importance in ensuring the safe and effective operation of any system where they are used. A hydraulic tube must be hard and strong enough to resist pressure and should also have a good level of resistance to corrosion and wear. Typically, the material used to construct a hydraulic tube will depend on the application and can range from metals such as steel, aluminum, brass and stainless steel to plastic.

Safety Considerations:

Safety considerations are always of the utmost importance when dealing with pressurized fluid or gas. Hydraulic tubes must not only be resistant to corrosion and wear but also need to be correctly connected and correctly used. It is important to ensure that all connections are tight, dry and free from dirt or other foreign material before use. If any tubes are damaged or show signs of leaking, they must be replaced immediately.

Applications of Hydraulic Tubes:

Due to the wide range of industries in which hydraulic tubes are used, there is a myriad of applications for these components. In the automotive sector, for instance, these are used for brakes, clutches, window regulators and air conditioning systems. In the aircraft industry, hydraulic tubes are used for door control mechanisms, wheels and landing gear systems. Industrial machinery often utilizes hydraulic tubes in press machine operations and welding processes, while plumbers and mechanics rely on them for plumbing and HVAC systems.

Conclusion:

Hydraulic tubes are essential components in some of the most complex systems and machinery. They are manufactured from steel, aluminum, brass and other materials to provide an efficient and reliable connection point. It is very important to take into account safety considerations when using this component and to ensure all connections are tight, clean and free from any foreign material. Furthermore, these tubes are versatile, and they are able to provide a strong and durable connection point for a wide range of applications in various industries.

Read more: Understanding the Different Types of Seamless Hydraulic Tubes

Eastern Steel Manufacturing Co., Ltd no solo mejora la producción de productos y los servicios de venta, sino que también brinda servicios adicionales de valor agregado. Siempre que lo necesite, podemos completar sus necesidades específicas juntos.

Eastern Steel Manufacturing Co., Ltd no solo mejora la producción de productos y los servicios de venta, sino que también brinda servicios adicionales de valor agregado. Siempre que lo necesite, podemos completar sus necesidades específicas juntos.