Difference : seamless vs welded pipe

With the continuous development of industrial applications, piping systems and products have been widely used in many construction fields. Manufacturers have doubled production rates over the past decade to meet market demand. Pipe forming can only follow two specific techniques which can produce seamless or

welded pipes. The first step is to cast crude raw materials such as ore or scrap metal into ingots. The final step in the manufacturing process is to shape the pipe by extending the seamless tube. There is a fine line between

seamless steel pipe and welded pipe. This article will provide a detailed overview of each method, its advantages and disadvantages, their differences, applications, and when to use them.

Overview of seamless steel

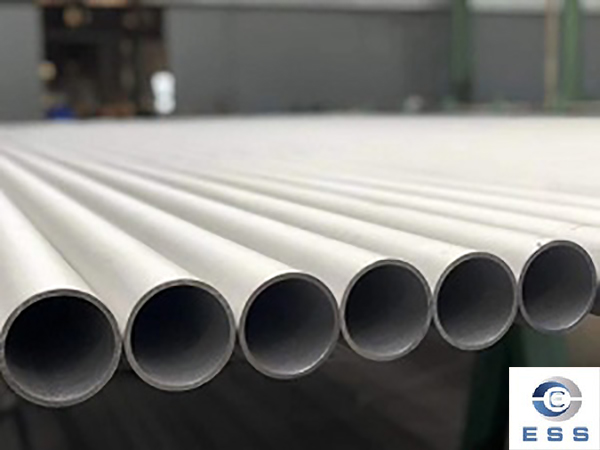

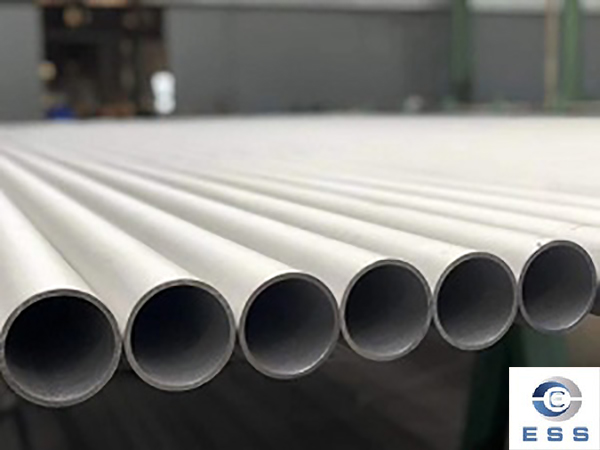

Seamless steel pipe is a steel pipe that is made of a single piece of metal and has no seams on the surface as opposed to welded pipes. As the name suggests, seamless steel pipe has no seams (creases) or welds.

Seamless Steel Tubes are characterized by perfect finishing, which is flawless and desirable, hence the higher demand. They are manufactured as round, rectangular or square, and the pipes are tubular (hollow) because most of them carry flowing substances such as gases, liquids, slurries and powders. Seamless steel is strong and durable as it is not welded and it has no joints; this means that the pipe has a uniform structure which ensures evenly distributed strength.

Application

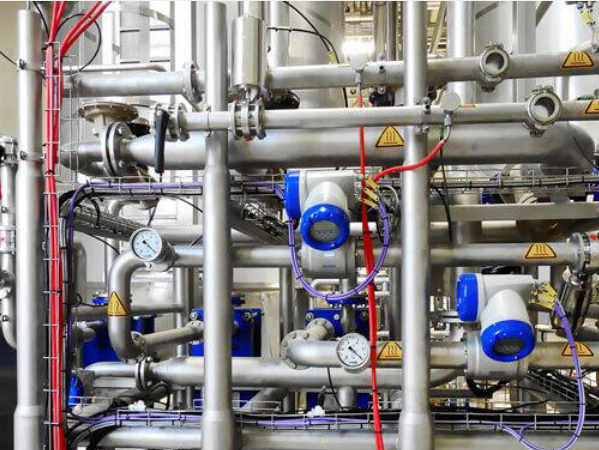

Seamless steel tubes have specific applications due to their unique properties such as uniform strength distribution, no welded joints, high temperature resistance, pressure bearing capacity, high quality, and better weight limitation.

How is seamless steel pipe made?

Seamless steel tubes are manufactured from a round piece of strong steel called a billet. The billet must be heated, then stretched, and finally pushed or rolled on a frame or form until the tube is hollow. Seamless steel pipes (ASTM and API 5L) adopt their shape through perforated pipe.

At this time, the seamless steel pipe is formed through the following process:

The manufacture of hot-rolled seamless steel pipes is from forging blanks, piercing, rolling, and shaping. The pipe is manufactured using an industrial extrusion process for the manufacture of thick-walled seamless steel pipes and large-diameter pipes.

On the other hand, the cold-drawn seamless steel pipe adopts the cold-drawing process, which is suitable for small-diameter, thin-walled pipes, and the material strength is low. It is also useful when the goal is to create fine looking pipes with smooth inner surfaces. In the extrusion process, seamless steel pipes can only be rolled with low alloy structure, carbon structural steel or alloy structure.

Some seamless steel pipes are often hardened during the manufacturing process; in this case, the manufacturer does not use heat treatment.

Overview of welded pipe

Welded steel pipe is a multi-million dollar industry. It is growing every day to meet the insatiable demand for welded pipes. Fortunately, today several sectors are involved in the mass production of welded steel pipes.

Welded steel pipes are always in plentiful supply due to their lower production costs and availability of raw materials. Therefore, it is one of the most widely used metals in the world. Its application in different industries and manufacture of countless products. Examples of ASTM or API 5L welded steel pipe include SSAW pipe, ERW steel pipe, and LSAW pipe.

Many people confuse ERW pipe with seamless steel because it doesn't use fused metal and the welds aren't always visible, nor can you feel them. In contrast, double submerged arc welding (DSAW) leaves a noticeable weld bead that can be removed using different processes depending on the method of application.

Application

Unlike seamless steel pipes, welded steel pipes are widely used in several industries due to their cost-effectiveness. They can also be manufactured in different lengths and welded from different shaped tubes. Application depends entirely on usage and other relevant factors.

How are welded steel pipes manufactured?

Most welded steel pipes are made of steel plates and strips. These strips and plates are produced by moving steel rings and coils using appropriate thickness gauges to form a flat material. Then measure the flat material and cut it to the desired length.

The process starts with bending a steel plate, which is then welded into the desired shape, be it round, rectangular, square, etc., using a series of benders or rollers. Metal pipe welding uses powerful energy. Some pipes can also be welded together with filler material. Most welded steel pipes must undergo a heat treatment process.

The weakest part of welded steel pipe is always the joint. The quality of the welded joint determines the quality of the welded pipe - robotic welding is mostly used in automated production lines, such as in the automotive industry. Or, for stronger steel pipe welds, artificial has proven perfect; for example, in aerospace construction.

The cost of seamless steel pipe vs. welded pipe

Strength and durability are some of the factors that determine the cost of welded and seamless pipes. Seamless steel is stronger than welded pipe and is more expensive due to higher production costs.

On the other hand, welded steel pipes are easier to manufacture due to their low production costs and readily available raw materials. In addition, the production process of seamless steel is complex and time-consuming. Since each pipe material has its own unique characteristics, advantages, and disadvantages, it is important to understand acceptable purchasing practices in order to develop a reasonable budget.

Healthy Purchasing Practices for Seamless and Welded Pipe

Good purchasing practices can minimize metal piping waste, which can greatly reduce material costs. It also ensures the best materials get the job done. Here are some tips to keep in mind for your next order:

1. Know your environment - The environment in which the metal pipe will be located should determine which metal pipe you will purchase. If you're in a less corrosive climate, you can opt for welded steel, but if you're in a highly corrosive environment, it's worth spending a lot of money on seamless steel because it will last longer.

2.Plan Ahead - Having a great job plan is the key to saving you thousands of dollars. A simple technique will help you know the exact amount of metal pipe of all expected dimensions. Hence, it makes it easier to source and place orders on time.

3. Contact an expert – Whether or not you are sure about what you want, always seek professional advice to be sure. Someone who has been in the field for decades has the kind of experience you need to budget and buy the right stuff. Contact our office for welded pipe and seamless steel

4. Place orders on time - Placing orders early allows you to plan your finances and buy the right pipeline. Placing an order is as easy as sending in pipe specs, getting a quote, and you'll have your shipment in no time.

Choose seamless or welded pipe

Welded steel pipes and seamless steel pipes are the two most common types of steel pipes on the market.As the name implies, seamless steel pipes are produced by hot rolling and cold rolling without joints.

Welded pipes, on the other hand, are made by rolling steel coils to the required standard thickness, a manufacturing process that leaves seams on the pipe body. The next stage is to cut the joints to a width corresponding to the size of the pipe to be built.

Electric resistance welded (ERW), spiral submerged arc welded pipe (SSAW) and longitudinal submerged arc welded pipe are three different forms of welded steel pipes (LSAW). The three welded steel pipes are manufactured in very different ways.

Most of the world's steel products are used in buildings, bridges and other infrastructure in the form of beams, pipes and foundation piles. It makes it possible to build tall buildings because steel can withstand the stresses created by the weight of the structure.

In addition to steel quality, architects and contractors must choose the type of steel pipe that is best for their project. For example, bridge foundations must be able to handle various environmental factors such as earthquakes, ship collisions and strong currents.

In those cases does it matter if they use seamless or welded pipe? Let's look at the differences.

About seamless steel pipe

Seamless pipes are designed by cold rolling or hot rolling extraction. The process hardens carbon or alloy steel to create a strong yet lightweight product. They take longer to make and are more difficult to get just the right size.

The advantage of seamless steel pipes is that they can generally withstand greater pressures, which makes them ideal for oil and gas industry applications. There are no seams exposed to corrosion, nor is it unsightly if the pipe is in a visible area. When you need very large pipes, the limitations of the production process make it not a good choice.

About welded steel pipe

Welded pipe starts out as flat metal sheet or strip. These are bent into shape and the edges are welded together. This means that the finished product can be very precise in diameter and wall thickness.

These are often used in construction where exact dimensions are critical, and are suitable for general use as they are usually the more affordable option. Because they can have multiple seams, welded pipes can be made in many different shapes and sizes, including oversized pipes for construction.

The downside is that these pipes usually have thinner walls which, along with the seams, make them more susceptible to stress. Slight impurities around seams can also expose them to potential corrosion.

Seamless steel pipe and welded steel pipe

Each type of plumbing has advantages and disadvantages depending on your end use. While seamless has a higher stress rating, it may not be your project's highest priority.

If you are building a bridge and need a lot of piles, the low cost and larger potential size of welded pipe may be more important.

Comparison of seamless steel pipe and welded pipe

|

|

seamless steel pipe

|

Welded steel pipe

|

|

application

|

Chemical processing plants

Manufacturing oil and gas lines

Manufacturing medical equipment

Hydraulics

Nuclear power plants

Water purification plants

High temperature and pressure units

Sensitive measuring units

|

Architecture

Food and beverage processing industries

Automotive industry

Aerospace construction

Pharmaceuticals

Marine and fishing

Construction and mining

Pipelines

|

|

Pros

|

Heavy and thick-walled

Has no welds

Corrosion resistance

Better ovality (roundness)

Durable

Better pressure capacity

No fusion metals used

No tests required for weld integrity

|

It can be manufactured in longer lengths

Less costly

No size restriction

Smoother surfaces

Readily available

Shorter delivery time

Thinner walls

Lighter in weight

Tighter tolerance

Consistency in wall thickness

|

|

Cons

|

Shorter in length because of manufacturing difficulties

Size restriction with a nominal size of 24 inches or less

Costly

The extrusion process makes it rough

Inconsistent wall thickness

|

Welds are prone to corrosion

It can only withstand 20% less weight

Must be tested before use

Poor ovality

|

|

Strength

|

Seamless pipes are able to withstand more pressure and load as there is no weak seam.

|

Due to welding, welded pipes are believed to withstand 20% less pressure and load as compared to seamless pipes.

|

|

Length

|

Seamless pipes are relatively shorter in length due to manufacturing difficulties.

|

Welded pipes can be manufactured in long continuous lengths.

|

|

Size

|

Seamless pipes are usually manufactured for a nominal size of 24 inches or less.

|

There is no such size restriction on welded pipe production.

|

|

Corrosion Resistance

|

Sealless pipes are less prone to corrosion means more corrosion-resistant.

|

The weld areas of the welded pipes are more prone to corrosion attacks, which means less corrosion resistance.

|

|

Surface Quality

|

The surface quality of seamless pipes is rough due to the extrusion process

|

Welded pipes have a smooth high-quality surface as compared to seamless pipes.

|

|

Economy

|

Costlier

|

More economic

|

|

Production Process

|

The production process of seamless pipe is quite complex with a long procurement lead time

|

The welded pipe production process is comparatively simpler with a short procurement lead time.

|

|

Tests

|

Seamless pipes do not require testing for weld integrity.

|

Welded pipes must be tested before use.

|

|

Availability

|

Less availability, limited material types, longer delivery time.

|

Readily available for various different materials; shorter delivery time.

|

|

Wall Thickness

|

Seamless pipes have inconsistent wall thickness across the length, thicker so heavier

|

Wall thickness for welded pipes is more consistent than seamless ones, thinner

|

|

Ovality

|

Seamless pipes provide better ovality, roundness

|

Welded pipes provide poor ovality and roundness as compared to their seamless counterpart.

|

|

Internal surface check

|

Checking not possible

|

The internal surface for welded pipes can be checked before manufacturing

|

Comparison of manufacturing methods of seamless pipes and welded pipes

As industrial applications evolve and become more complex, plumbing products and the systems that serve them must keep pace. While many methods of pipe fabrication exist, the most prominent discussion in the industry is comparing electric resistance welded (ERW) versus seamless (SMLS) steel pipe.

Both ERW and seamless pipe fabrication methods have been used for decades; the methods used to produce each have improved over time. So which is better?

Manufacture of welded pipe

Welded pipe begins as a long coiled strip of steel called a skelp. Cut the skelp to the desired length, resulting in a flat rectangular slab. The width of the shorter end of this sheet will become the outer perimeter of the pipe, which is used to calculate its final outer diameter.

Rectangular sheets are fed through a coiling machine whose long sides are coiled over each other to form a cylinder. In the ERW process, high-frequency current is passed between the edges, causing them to melt and fuse together.

An advantage of ERW pipe is that no fused metal is used and there is no weld seam to be seen or felt. This is in contrast to double submerged arc welding (DSAW), which leaves a noticeable weld bead that must then be removed depending on the application.

Welded pipe manufacturing techniques have improved over the years. Perhaps the most important advancement was the switch to high-frequency currents for welding. Before the 1970s, low frequency currents were used. Welds produced by low frequency ERW are more prone to corrosion and weld failure. Most welded pipe types require heat treatment after fabrication.

Manufacture of seamless pipes

Seamless pipe begins with a solid cylindrical block of steel called a billet. The billet is pierced from the center with a mandrel while it is hot. The next step is to roll and stretch the hollow billet. Billets are precisely rolled and drawn until they reach the length, diameter and wall thickness specified by the customer's order.

Some seamless pipe types harden as they are manufactured and therefore do not require heat treatment after manufacture. Others do require heat treatment. Consult the specifications for the type of seamless pipe you are considering to see if it requires heat treatment.

Historical Perspective and Use Cases of Welded vs Seamless Steel Tubes

ERW and seamless steel tubes exist as substitutes today mainly due to historical perception. Generally, welded pipe is considered inherently weaker because it contains welds. Seamless pipes do not have this perceived structural defect and are considered safer. While welded pipe does contain theoretically weaker seams, both manufacturing techniques and quality assurance programs have improved to the point that welded pipe will perform as intended when its tolerances are not exceeded. While the obvious advantages are obvious, a criticism of seamless pipe is that the rolling and drawing process produces inconsistent wall thicknesses compared to the more precise steel plate thicknesses used for welding.

Industry standards governing the manufacture and specification of ERW and seamless steel tubes still reflect these perceptions. For example, many high-pressure, high-temperature applications in the oil and gas, power generation, and pharmaceutical industries require seamless tubing. Welded piping (which is generally cheaper to produce and more widely used) is regulated in all industries as long as temperature, pressure, and other service variables do not exceed the parameters specified in the applicable standard.

In structural applications, there is no difference in performance between ERW and seamless steel tubes. While the two can be specified interchangeably, it doesn't make sense to specify seamless when cheaper welded pipe works just as well.

Good purchasing practice for welded and seamless steel pipes

An important thing to note when specifying piping products for a project is that the specification manuals that engineers use to guide the specifications they write (such as those provided by ASTM, ASME, ANSI, and API, etc.) list only piping grades without citing either Are they produced by ERW or seamless pipe fabrication. Not all grades can be produced either way.

Eastern Steel Manufacturing Co., Ltd no solo mejora la producción de productos y los servicios de venta, sino que también brinda servicios adicionales de valor agregado. Siempre que lo necesite, podemos completar sus necesidades específicas juntos.

Eastern Steel Manufacturing Co., Ltd no solo mejora la producción de productos y los servicios de venta, sino que también brinda servicios adicionales de valor agregado. Siempre que lo necesite, podemos completar sus necesidades específicas juntos.