The wonders of pipe beveling: Faster, easier, safer

In recent years, the process of pipe beveling has become increasingly popular among industrial professionals around the world. Pipe beveling, while requiring some skill and knowledge of equipment, is a relatively simple task that can save time and reduce the risk of accidents and injury. In this essay, we will look into the reasons and benefits of using this process to bevel pipes, as well as examining the tools and techniques used to accomplish the task.

The primary benefit of pipe beveling is that it guarantees a high-quality end product, requiring less finishing and fewer adjustments than standard cutting methods. With a beveled edge, any flow restriction is greatly reduced, allowing for improved fluid dynamics and increased pressure capacity. This can be very helpful in engineering applications such as plumbing or firefighting. Additionally, the use of a beveled edge also eliminates the need for grinding or welding operations, as the angle is already slightly adjusted. This reduces the cost and time needed in many manufacturing processes.

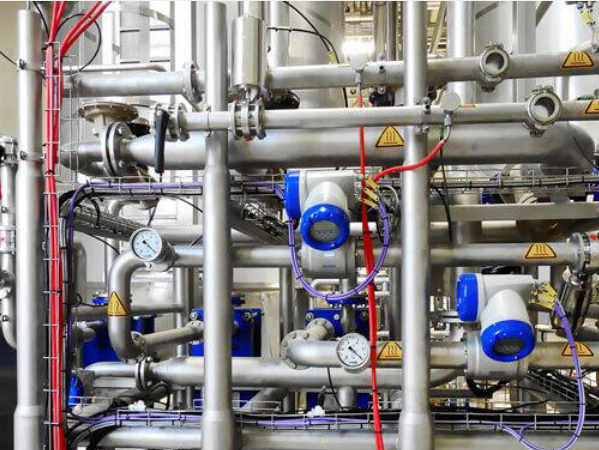

When talking about pipe beveling, the first thing to mention is the tools used to accomplish the task. Though there are several varieties available in the market, the most commonly used tool is the beveling machine. This machine typically consists of a pair of rollers mounted on opposite sides of the pipe, which are adjustable to the desired angle and speed. The rollers spin simultaneously and exert pressure on the material being machined, creating the desired profile. These machines offer a great degree of versatility and accuracy, and can produce a wide range of angles, from 0° to 60° depending on the make and model.

Outside of their practical application, pipe beveling also offers a much greater degree of safety. As previously mentioned, they help minimize the risk of accidents by reducing the chances of sharp edges forming on the ends of the pipe. This helps avoid potential injuries due to contact with the edges. Additionally, beveling eliminates the need for additional welding and grinding operations, thus eliminating additional sparks and fumes which could prove hazardous.

There are a few tips that industrial professionals should keep in mind when working with pipe beveling. First and foremost, it’s essential to ensure that the machine is at the correct speed and angle when performing the beveling. Also, be sure to check the material being cut for any imperfections or deformations before beginning the process. Lastly, always wear protective gear such as gloves and eyewear to protect yourself from flying debris.

In conclusion, pipe beveling is an effective, safe, and economical way to create perfectly finished pieces. It requires minimal effort, reduces the risk of injury, and cuts down significantly on the costs associated with traditional cutting methods. The tools required to accomplish the task can be found readily available, and there is a wide variety of machines designed to meet any application. For all these reasons, it’s easy to understand why pipe beveling has become the go-to method for industrial professionals around the world.

Eastern Steel Manufacturing Co., Ltd no solo mejora la producción de productos y los servicios de venta, sino que también brinda servicios adicionales de valor agregado. Siempre que lo necesite, podemos completar sus necesidades específicas juntos.

Eastern Steel Manufacturing Co., Ltd no solo mejora la producción de productos y los servicios de venta, sino que también brinda servicios adicionales de valor agregado. Siempre que lo necesite, podemos completar sus necesidades específicas juntos.